Made to handle the flow

We offer several wide-gap plate geometries designed to handle larger fibers and keep flows moving longer between cleanings.

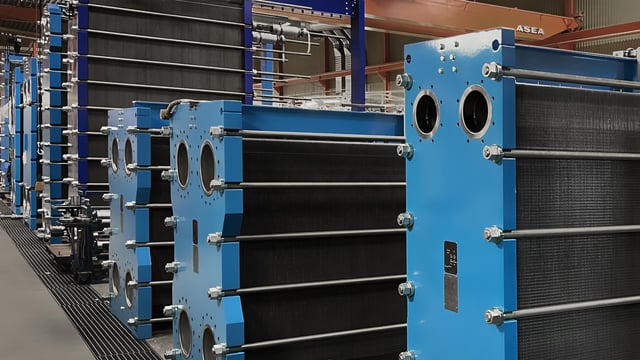

Improve efficiency with Tranter heat exchangers

In pulp and paper production, fibrous, solids-heavy streams foul and clog exchangers fast, while aggressive bleaching chemicals accelerate corrosion and nonstop schedules leave little room for downtime.

That’s why Tranter plate heat exchangers are built with fouling-resistant and durable materials, and service-friendly designs. Our solutions help you cut cleaning intervals, lower energy use, and keep production on track.

Pulp and paper industry

We offer several wide-gap plate geometries designed to handle larger fibers and keep flows moving longer between cleanings.

Our solutions come with easily openable frames and quick reassembly that cut cleaning hours and downtime.

We design exchangers that capture more heat from water loops, bleaching, and drying to reduce steam demand and fuel costs.

The stainless and other alloy plates in our exchangers work against bleaching agents and harsh process media.

Tranter’s global supply chain and service ensure your exchangers, OEM parts, and spares arrive on time.

Tranter experts design heat exchangers tailored to your mill conditions, maximizing reliability, OPEX and ROI.

.jpg?width=640&height=358&name=d09b103d-0b24-40ce-86eb-821128dc9471%20(1).jpg)

Pulp and paper industry

Stable thermal performance that reduces energy intensity and helps control steam costs.

Fouling-resistant exchangers keep fiber-rich pulping streams under control, extending uptime between cleans.

Support boilers and steam loops with exchangers that recover heat, improve efficiency, and cut fuel demand.

Why Tranter

References across pulp and paper operations globally.

90+ years of heat exchanger thermal design and engineering.

Local service centers and spare parts where and when you need them.

Configured specifically for fouling-prone, chemical-heavy conditions in pulp and paper production.

Tranter’s R&D is on a constant mission to develop anti-fouling plate geometries and chemical-resistant materials to extend cleaning intervals and reduce downtime even further.

Combined with compact layouts that boost energy recovery, our exchangers help mills cut maintenance costs and stay competitive in an energy-intensive industry.

With Tranter FullServ®, you get lifecycle support for every brand of heat exchangers. We keep your equipment running, from inspection and reconditioning to emergency on-site service.

Our rapid-response teams and local service centers around the world ensure your exchangers deliver peak performance longer.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Resource center

Still curious?