Engineering hours

Maximize the benefit of our engineering expertise by utilizing our services as extensively as possible. Our team is dedicated to providing top-tier solutions tailored to meet your unique project requirements.

Pulp and paper industry

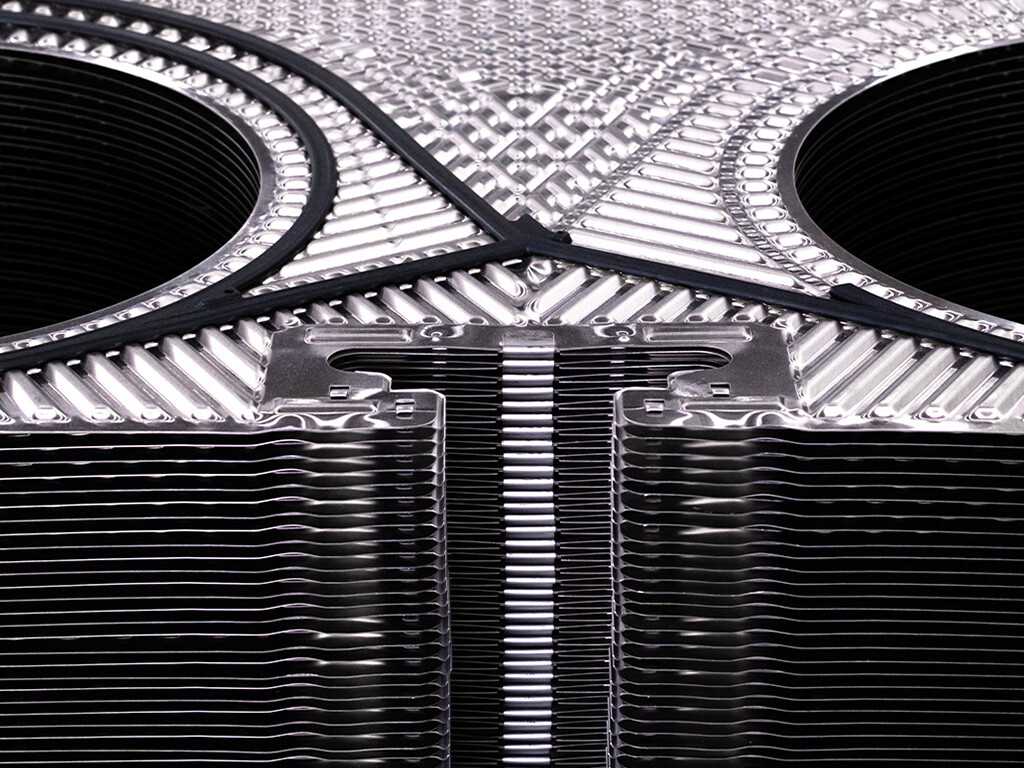

Pioneering advancements in energy optimization, our efforts elevate efficiency and sustainability for the pulp and paper production processes like pulping, steam generation, and paper drying. Tranter’s plate heat exchangers provide precise temperature control during the pulping stages, ensuring optimal conditions for the fiber separation and chemical reactions.

Pulp and paper industry

Maximize the benefit of our engineering expertise by utilizing our services as extensively as possible. Our team is dedicated to providing top-tier solutions tailored to meet your unique project requirements.

Gain immediate, expert advice on streamlining projects to drastically cut down on administration time. Tranter combines small-company agility and customer focus, ensuring personalized attention to every customer's needs.

We understand how critical it is for our customers to meet or even surpass project timelines. It's for this reason we are committed to ensuring deliveries are not just on time, but guaranteed to be prompt.

Pulp and paper industry

Heat exchangers are employed in paper drying machines to remove moisture from the paper web. They provide the necessary heat to evaporate water from the paper surface, ensuring proper drying and improving paper quality.

Heat exchangers are utilized in the pulping process, where wood chips or other raw materials are converted into pulp. Tranter’s efficient plate heat exchangers help control temperatures during the pulping stages, such as chemical pulping (kraft or sulphite processes) or mechanical pulping (refining or grinding), ensuring optimal conditions for fibre separation and chemical reactions, while being easy to maintain and adjust for changed process conditions.

The pulp and paper industry requires significant amounts of steam for various purposes, including drying paper, heating processes, and power generation. Tranter’s plate heat exchangers are employed in steam generation systems to transfer heat from hot gases or liquids to water, producing steam efficiently, thus improving the total economy and sustainability of the plant.

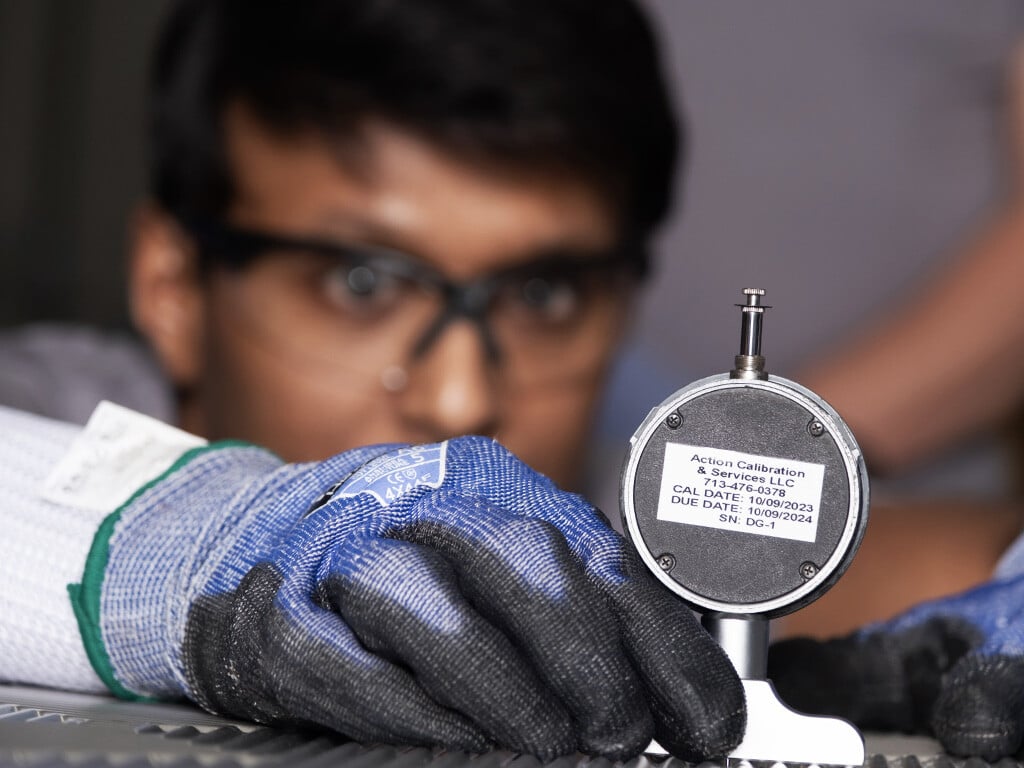

Our comprehensive understanding of heat exchangers goes beyond just maintenance and usage. We offer tailored recommendations and innovative solutions to optimize your system's performance, reduce energy consumption, and extend the lifespan of your equipment. Our goal is to not only enhance your operational efficiency but also to ensure the long-term health and reliability of your heat exchangers. Trust Tranter to provide expert insights that keep your systems running smoothly and cost-effectively.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Resource center

Still curious?