Internal workload

Our commitment lies in harmonizing work-life equilibrium for your team, guaranteeing that tasks are completed efficiently and on schedule.

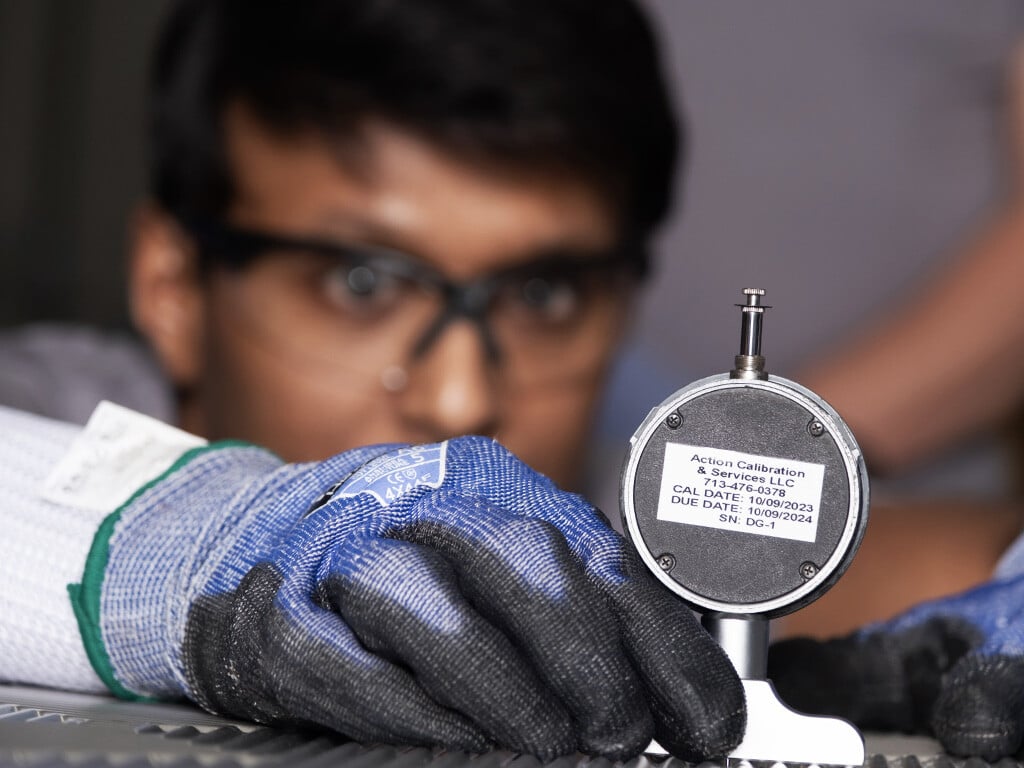

Enhancing manufacturing efficiency, energy conservation, and quality

Industrial cooling systems are critical to ensuring equipment works properly in manufacturing and general industries. Therefore, selecting the ideal cooling solution is very important, particularly for facilities that handle high volumes or require delicate temperature management. Considering industrial heat exchangers can be a game-changer in such scenarios.

Manufacturing and machinery

Our commitment lies in harmonizing work-life equilibrium for your team, guaranteeing that tasks are completed efficiently and on schedule.

Maximize the benefit of our engineering expertise by utilizing our services as extensively as possible. Our team is dedicated to providing top-tier solutions tailored to meet your unique project requirements.

Minimize your project expenses effectively by implementing strategic cost-saving measures. Adopting efficient planning, and ongoing cost analysis can dramatically reduce unnecessary expenditures.

Manufacturing and machinery

In the automotive industry, heat exchangers uses innovative materials and technology to meet the industry's high standards. Tranter is able to offer a range of heat exchangers designed to cater to every aspect of automotive manufacturing operations, from the initial stamping process to the final assembly and paint lines.

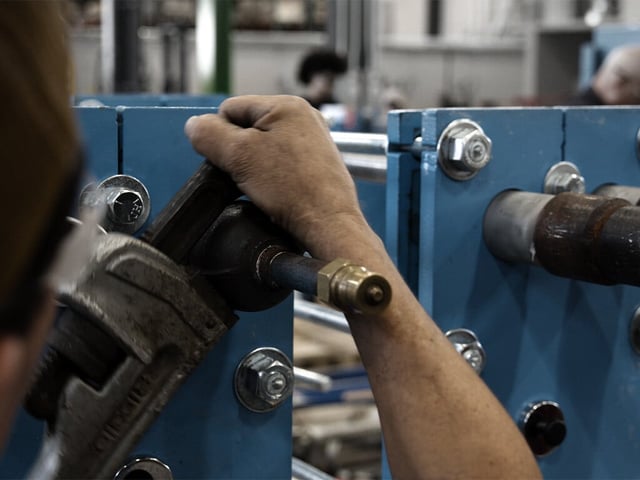

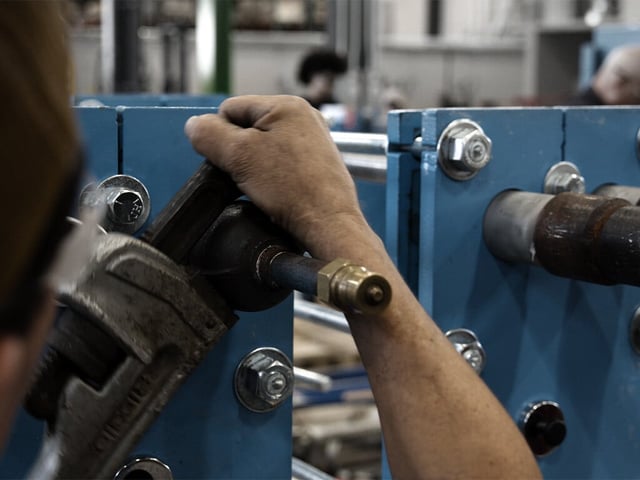

Gasketed plate heat exchangers can be designed to provide flexibility to meet the demands of any oil cooling application. Suitable for hydraulic and lube oil systems for small and high flow demands combined with a low pressure drop demand. Tranter add value to compressor and turbomachinery lube oil systems by supplying complete lubrication oil cooler skids.

As in every industry, the heating or cooling of materials necessitates a designed thermal process, ensuring temperatures are precisely adjusted to meet the specific requirements of each application. Within the metal work industry, the complexity of processes continually escalates, demanding the utilization of advanced heat exchange technology to manage the fluids temperatures and pressures effectively. Various pressing, cutting and shaping methods of metals also require safe and reliable lubrication oil systems. Here is where a plate heat exchanger can support in metal work industry.

Compressor manufacturing is a specialized segment of the machinery industry focused on compression of various gases making them critical components in various applications, including ORC systems, refrigeration, industrial processes, and automotive systems. Heat exchangers play an essential role in compressor systems to cool and condense liquids from the compressed gas and as lubrication oil coolers for the compressors for a long and reliable lifetime of the compressors.

Diesel engines, known for their efficiency and durability, use compression heat to ignite fuel, excelling in producing high torque at low speeds. Heat exchangers are used to cool the engine coolant. This prevents the engine from overheating during operation, ensuring optimal performance and longevity. Tranter’s compact plate & frame heat exchangers can be built-on the diesel engines as an integrated part of the system.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Resource center

Energy, Process industries Marine and shipbuilding Sustainability

Energy, Process industries Marine and shipbuilding Sustainability

Resource center

Still curious?