Engagement and interaction

Receive instant, professional guidance on optimizing your projects for significant reductions in administrative workload.

Advancing efficiency, energy savings in bulk carriers

Bulk carriers, also known as bulkers, are ships specifically designed to transport unpackaged bulk cargo, such as grains, coal, ore, and cement, in their cargo holds. These ships play a crucial role in the marine industry, facilitating the movement of large quantities of raw materials across the globe. They are a cornerstone of the marine industry, designed to transport large quantities of raw materials efficiently and economically.

Bulk carriers

Receive instant, professional guidance on optimizing your projects for significant reductions in administrative workload.

Receive customized and comprehensive project execution plans from our professionals. We guarantee your success by customizing technology solutions that align perfectly with your objectives.

We understand the challenges when strategies exceed budgets, driving us to explore cost-effective alternatives. Our focus is on finding the most affordable solutions.

Bulk carriers

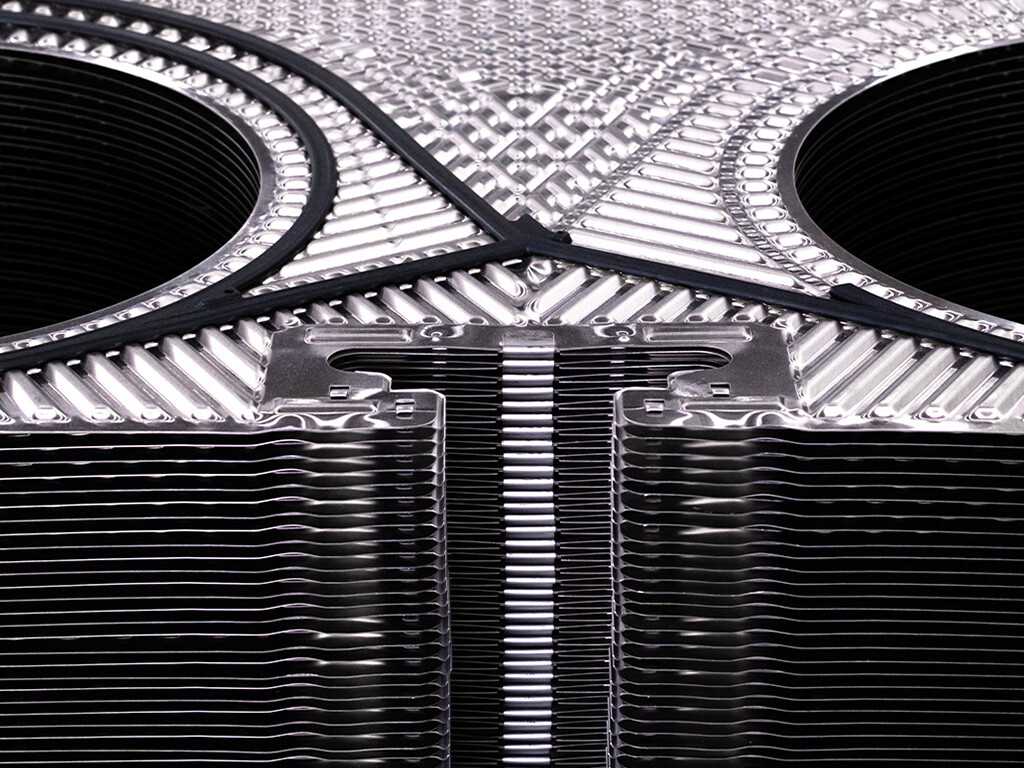

Clean fuel engines combined with efficient heat exchangers represent a significant advancement in making bulk carriers more sustainable. These technologies not only comply with stringent environmental regulations but also enhance fuel efficiency and operational performance.

Marine engines in various vessels face tough conditions and produce a lot of heat. Cooling systems are crucial to dissipate this heat, avoiding overheating, potential engine failure, and expensive repairs. Heat exchangers play a key role in preventing overheating and maintaining efficiency.

Heat exchangers prevent lubricating oil in marine engines and machinery from overheating, preserving its effectiveness and protecting engine components.

Our comprehensive understanding of heat exchangers goes beyond just maintenance and usage. We offer tailored recommendations and innovative solutions to optimize your system's performance, reduce energy consumption, and extend the lifespan of your equipment. Our goal is to not only enhance your operational efficiency but also to ensure the long-term health and reliability of your heat exchangers. Trust Tranter to provide expert insights that keep your systems running smoothly and cost-effectively.

resource center

Parts and services

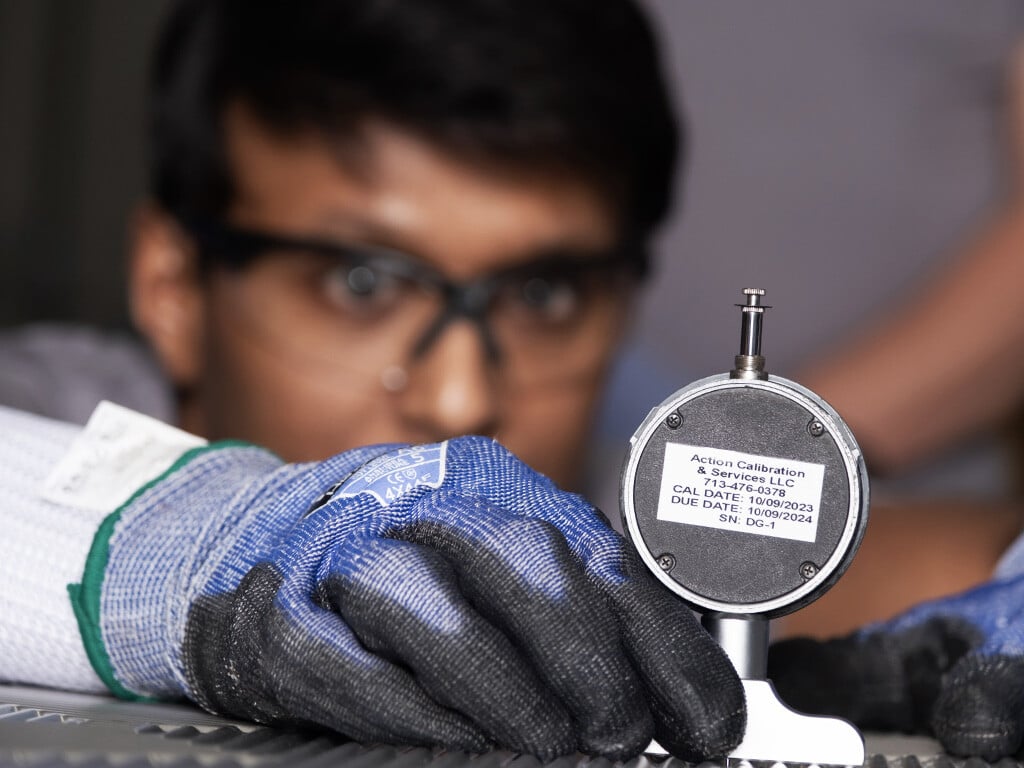

When it comes to inspection and plate removal, it's crucial to pay attention to every detail. By following the necessary steps and taking the time to inspect and remove plates properly, we can ensure that your project is completed successfully. Learn more by listening to Dave Lusignolo, Director, Aftermarket Sales - North America

Parts and services

Chemical cleaning and rinse are essential steps in maintaining the performance of your heat exchanger. Whether it's removing liquids, or ensuring the longevity of machinery, chemical cleaning and rinse play a crucial role in the service process.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Resource center

Still curious?