Reliability

Our specialists ensure maximum efficiency and uptime in mining and minerals, offering global support to boost productivity and energy savings through optimized industrial processes.

Mining heat exchangers

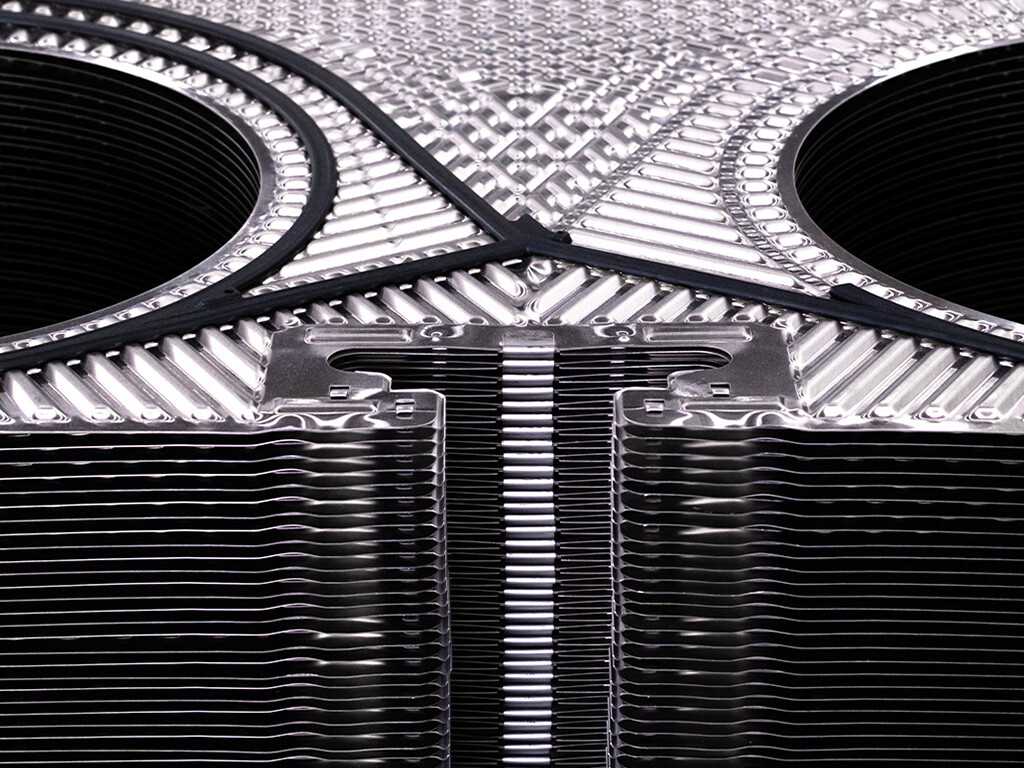

In mining operations, heat exchangers play a crucial role in maintaining optimal temperatures for various processes. Water with high mineral content in these processes tend to cause scaling, thus Tranter gasketed plate and frame heat exchangers that are easy to maintain is the preferred choice. Our plate heat exchangers are efficient, reliable and proven designs in many mineral processing applications, for heating and cooling duties as well as waste heat recovery applications. By utilizing appropriate heat exchangers technology, mining operations can enhance energy efficiency, improve equipment reliability and reduce their environmental impact.

Mining and minerals

Our specialists ensure maximum efficiency and uptime in mining and minerals, offering global support to boost productivity and energy savings through optimized industrial processes.

We understand how critical it is for our customers to meet or even surpass project timelines. It's for this reason we are committed to ensuring deliveries are not just on time, but guaranteed to be prompt.

Get efficient, detailed project execution plans on time from our experienced experts. We ensure significant energy and space savings by integrating the right technologies for your needs.

Mining and minerals

Overall, heat exchangers contribute to the sustainable and efficient production of copper by optimizing energy usage, controlling temperatures, and mitigating environmental impacts associated with heat-intensive processes. Their versatile applications make them indispensable components in the copper production industry, enabling cost-effective and environmentally friendly operations.

Lithium is an essential component in many of the emerging clean energy technologies. Lithium is found in rock ores or in briny water where it can be extracted using evaporation. Tranter’s plate heat exchangers with plates in high alloy and nickel alloys can be employed for the briny water or for the acids needed for the mining process.

Zinc sulfide concentrates are heated in roasters to convert them into zinc oxide and sulfur dioxide. Heat exchangers are used to preheat the air fed into the roasters, improving energy efficiency by utilizing waste heat from other parts of the process. In electrolytic refining, heat exchangers help control the temperature of electrolyte solutions used to dissolve impurities from the zinc.

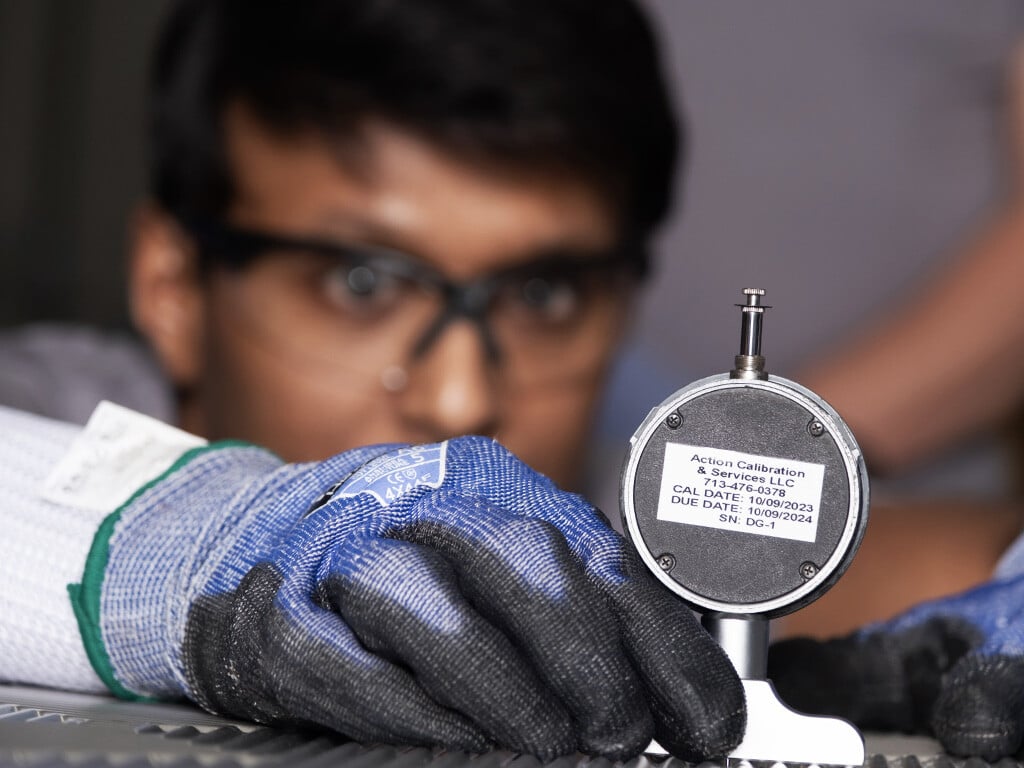

Our comprehensive understanding of heat exchangers goes beyond just maintenance and usage. We offer tailored recommendations and innovative solutions to optimize your system's performance, reduce energy consumption, and extend the lifespan of your equipment. Our goal is to not only enhance your operational efficiency but also to ensure the long-term health and reliability of your heat exchangers. Trust Tranter to provide expert insights that keep your systems running smoothly and cost-effectively.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Resource center

Still curious?