Counter flow heat exchangers

If thermal efficiency is mission-critical in your process, how your heat exchanger moves fluid matters. A counter flow heat exchanger sends hot and cold streams in opposite directions, maximizing the temperature gradient and squeezing out every bit of heat transfer.

It’s a setup built for performance. Unlike parallel or crossflow designs, counter flow systems can hit tighter temperature approaches with less surface area, making them a smart choice where space, energy, or precision are at a premium.

This page breaks down how a counter flow heat exchanger works, where it is the most suitable, and why it’s an engineering decision that pays off when done right.

What are counter flow heat exchangers?

A counter flow heat exchanger, also called counter current heat exchanger, is a system where two fluids move in opposite directions through the exchanger—one hot, one cold. This setup creates a consistent temperature difference across the entire flow path, driving more efficient heat transfer than other designs.

To put it simply: a counter flow heat exchanger is designed to make the most of every degree. Unlike parallel flow, where both fluids enter from the same side, counter flow maintains a higher temperature gradient from inlet to outlet. That makes a big difference when trying to reach specific outlet temperatures or recover waste heat more effectively.

You’ll often see this configuration in shell and tube designs or custom plate-based systems where thermal performance is the top priority. It’s a popular setup used in industries like central heating, power generation, and industrial processes. But also in applications for home usage, like ventilation systems and air conditioning. The counter flow heat exchanger formula, typically derived from NTU (Number of Transfer Units) and effectiveness calculations, confirms what plant operators already know: higher temperature differentials over longer distances equal better efficiency.

Common types

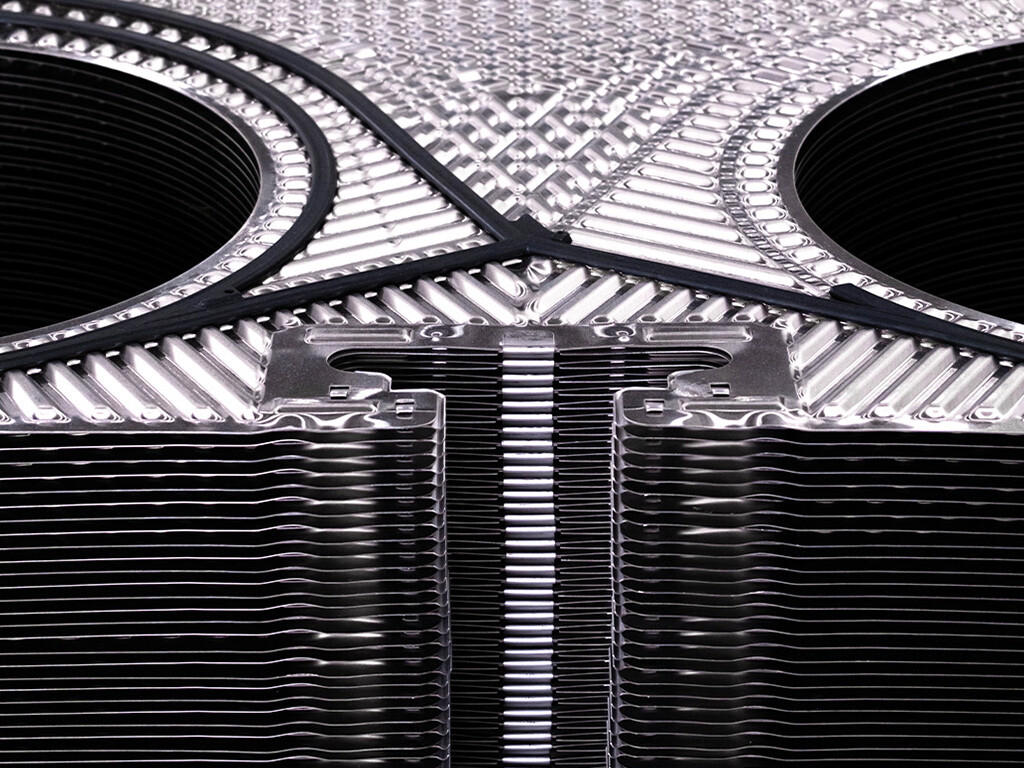

There’s no single build that defines counter flow heat exchangers—the layout is all about how the fluids move, not the hardware itself. That means several exchanger types can be engineered to run in a counter flow configuration, depending on the process and performance requirements. A counter flow heat exchanger is simply a common configuration that can be applied to several types of heat exchangers.

You’ll find counter flow designs in plate and frame, welded plate, and shell and tube systems. Spiral heat exchangers are another example, where the spiral geometry naturally lends itself to counter flow. Even finned tube exchangers and air-to-liquid systems can be adapted for counter flow setups when efficiency is key.

One variant to know is the cross counter flow heat exchanger. This hybrid design blends directional flows—partially counter, partially cross—to balance space constraints with better heat transfer. It’s often used in HVAC and energy recovery units where pure counter flow isn’t feasible but thermal performance still matters.

It’s important to mention that counter flow isn’t tied to a single product line. It’s a strategy. And in the right configuration, it can be built into almost any exchanger format that supports opposing fluid paths.

Comparison towards cross- and parallel flow

The way fluids move through a heat exchanger defines how well the system performs. In a counter current heat exchange mechanism, hot and cold fluids flow in opposite directions, maintaining a high temperature gradient across the entire exchanger. That gradient is what drives superior heat transfer.

Now compare that with parallel flow. In a parallel counter flow heat exchanger setup, also called co-current, both fluids enter the unit from the same end and move in the same direction. The result? The temperature difference between fluids drops quickly, limiting how much heat can be transferred. You might hit equilibrium halfway through the unit, which means wasted potential and less control over outlet temperatures.

Then there’s the cross flow vs counter flow heat exchanger comparison. Cross flow systems run fluids at right angles. They’re compact, easy to integrate, and common in HVAC or air-cooled applications — but they sacrifice efficiency. Since the fluids only partially overlap, the temperature gradient is inconsistent, leading to lower overall performance.

That’s where counter flow stands apart. By continuously exposing the hottest fluid to the coldest, it extracts more energy and delivers tighter outlet targets. You can cool process fluids closer to ambient (or recover waste heat more effectively) without oversizing the unit.

In short:

- Parallel flow is simple, but inefficient.

- Cross flow is compact, but limited.

- Counter flow is engineered for performance—and the results speak for themselves.

If your spec sheet demands tighter control or you’re pushing to reduce energy consumption, counter flow is likely the only setup that’ll meet the numbers.

Applications and use cases

You don’t invest in a heat exchanger for theory. You invest because your process demands results. And in that regard, counter flow heat exchanger applications stand out in industries where thermal precision, energy recovery, or compact design are non-negotiable.

A common application for counter flow heat exchangers is in chemical processing, where precise outlet temperatures are critical for reaction control and product consistency. The consistent temperature gradient in a counter flow setup helps maintain process stability, even as loads fluctuate.

Power generation and waste heat recovery also lean heavily on counter flow systems. Whether it’s capturing heat from exhaust gas or improving boiler efficiency, counter flow allows tighter heat transfer without adding unnecessary bulk to the system. Every degree recovered reduces fuel use. And that adds up fast.

In HVAC and refrigeration, counter flow units are found in energy recovery ventilators, chillers, and condensers. They help improve system COPs (coefficients of performance) by transferring more energy with smaller units, ideal for space-constrained or high-efficiency builds.

You’ll also find them in marine systems, the metallurgical industry, the petrochemical industry, oil and gas processing, food and beverage, and pharmaceutical plants. Basically anywhere process temperatures matter and energy efficiency can’t be compromised. For instance, in pharmacy, they’re used in drug production processes, and in food production, for pasteurization and drying, and to quickly cool or heat food products.

Pros and cons

If you’re measuring by raw thermal performance, counter flow heat exchanger effectiveness outpaces most other flow configurations. That’s the primary advantage: higher efficiency in a smaller footprint. But like any design, it comes with trade-offs.

Pros

- Superior heat transfer: With opposing flow paths, the temperature difference between fluids remains high throughout the unit, making counter flow the most efficient setup for achieving tight temperature approaches.

- Compact design: Because of the increased effectiveness, you often need less surface area to achieve the same duty—saving space and reducing material costs.

- Energy savings: Recovering more heat means running your system leaner. In plants where energy costs are under scrutiny, this adds up quickly.

Cons

- More complex flow management: Routing fluids in opposite directions may require more careful piping or tighter installation tolerances.

- Potentially higher pressure drop: With tighter channel designs to maximize performance, counter flow setups can introduce more resistance—something to factor into your pump sizing and system head.

- Not always the best fit: For simple duties or where temperature cross isn’t a priority, other flow types may offer a cheaper, simpler alternative.

Still, when effectiveness matters — when you’re aiming to do more with less — counter flow remains the gold standard. It’s a tool built for performance, and when used in the right context, it delivers every time.

Counterflow design is where efficiency lives, where every degree recovered is one less lost. Tranter heat exchangers are built on that same logic: maximize transfer, minimize waste. Explore the full range of Tranter solutions engineered for performance that lasts.