Energy transition

Explore how our heat exchangers play essential roles for breakthrough advancements in carbon capture, green hydrogen, energy storage, fuel cells, power-to-X technologies, and innovative recycling and circular solutions.

Energy process industries

Tranter's extensive worldwide expertise

Explore how our heat exchangers play essential roles for breakthrough advancements in carbon capture, green hydrogen, energy storage, fuel cells, power-to-X technologies, and innovative recycling and circular solutions.

Digitalization, electrification and the energy transition require several precious mineral ores, including lithium, nickel and cobalt, as well as platinum, gold and silver. Tranter’s plate heat exchangers enable mining operations processes to boost energy efficiency, reliability, save space and reduce environmental impact with advanced heat exchanger technology.

Heat exchangers are vital for efficient heat transfer and energy use in upstream and downstream crude oil and natural gas processing, enhancing safety and ensuring smooth industry operations.

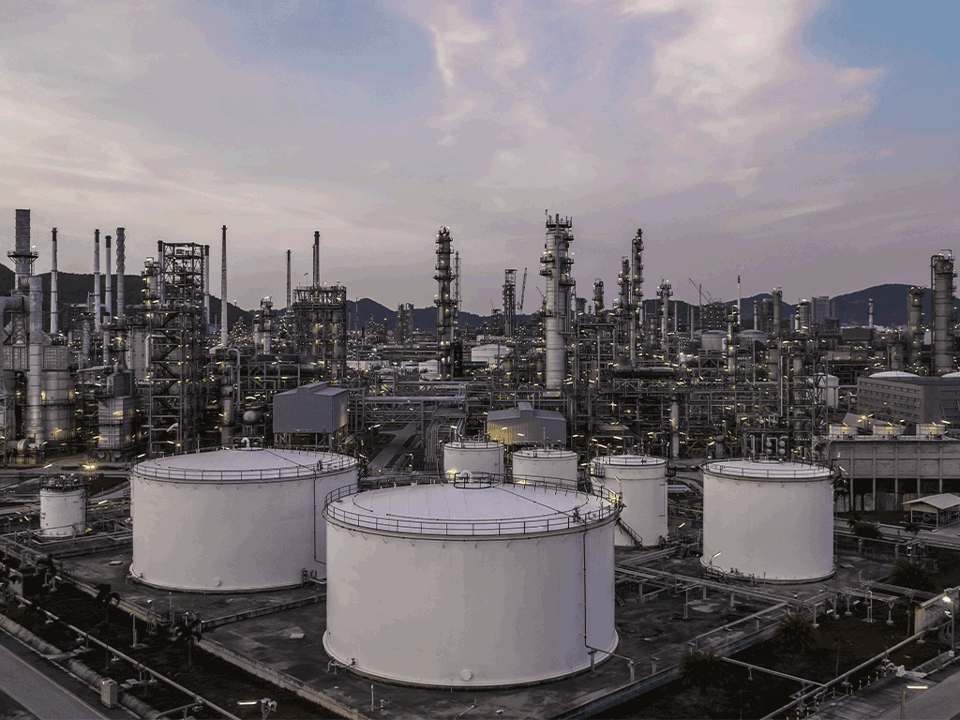

Heat exchangers optimize energy usage, enhance safety, and contribute to the production of a wide range of petrochemical products, including plastics, polymers, aromatic chemicals, ethylene and propylene, as well as organic and inorganic chemical processing.

Heat exchangers play an important role in supporting numerous secondary processes in the pulp and paper sector, including wastewater management, chemical recuperation, and energy co-production facilities.

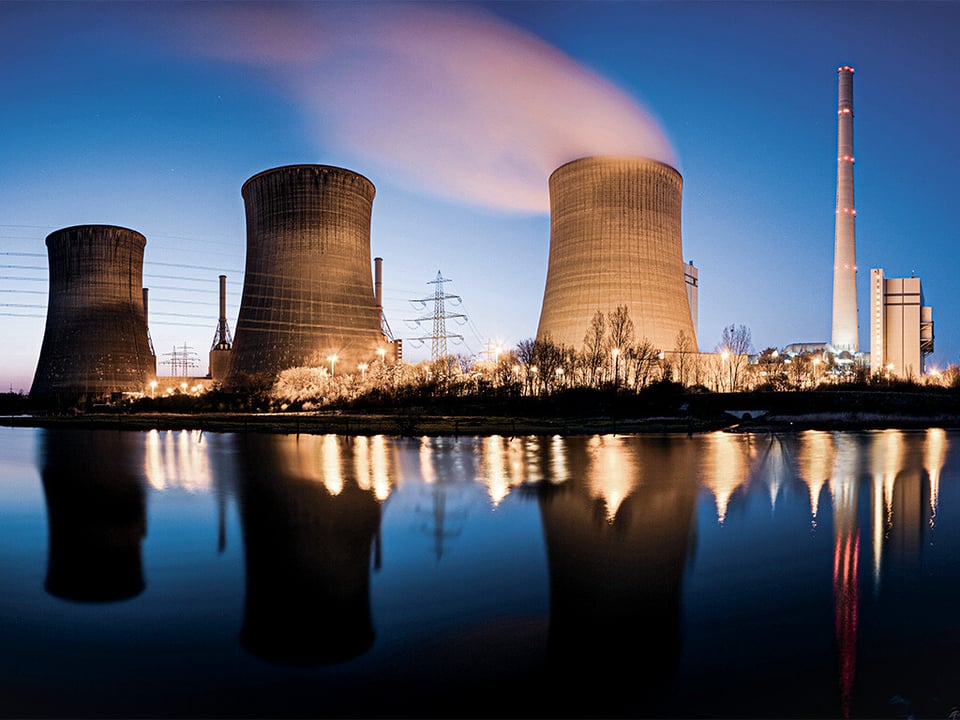

Heat exchangers boost efficiency and sustainability in various power plants, including combined heat and power plants, coal power, natural gas fired power plants, nuclear, and renewable power generation.

Heat exchangers are vital components within refineries, playing a crucial role in several key processes when processing crude oil in atmospheric and vacuum distillation, fluid catalytic cracking, alkalization process into various refined products such as gasoline, diesel, jet fuel and feedstock to petrochemical plants.

Heat exchangers play crucial role for the use of renewable energy sources like solar, wind, water, and geothermal to generate heat and power. Plate heat exchangers provide precise temperature control, increasing the efficiency of renewable energy plants and ensuring efficient waste heat recovery.

The renewable fuels and chemicals industry focuses on the production of biofuels, biogas, and biochemicals from renewable biomass sources such as plants, algae, and waste materials. Tranter’s plate and frame heat exchangers play a crucial role in reducing energy consumption, greenhouse gas emissions, and advancing sustainability in the renewable fuels production process.

The steel production industry involves the manufacturing of alumina, stainless steel and carbon steel from raw materials such as iron ore, coal, and limestone through processes like smelting and refining. Heat exchangers play a critical role in several stages of steel production to reduce the energy consumption, increase waste heat recovery and to make the industry more sustainable.

Our heat exchangers

INNOVATION AND PRODUCT DEVELOPMENT

resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Resource center

Anything else we can do for you?