Budgetary constraints

We understand the challenges that arise when proposed strategies exceed budget constraints, forcing a reconsideration and exploration of alternative solutions. Our dedication is to finding the most cost-effective approaches.

Encompassing the production of natural energy

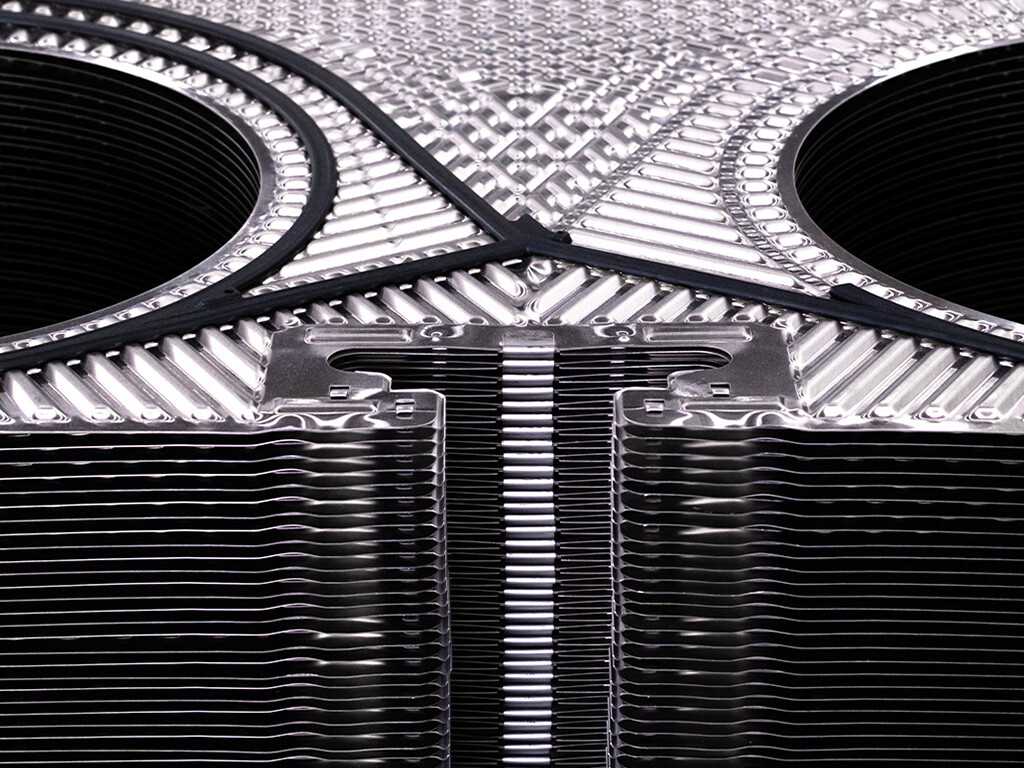

The renewable energy sector is dedicated to capturing the power of naturally renewable resources like sunlight, wind, water, and geothermal heat for electricity generation, along with heating and cooling purposes. These sources of energy present sustainable options that significantly reduce environmental footprints. Heat exchangers are crucial in a wide array of applications within this field.

Renewable energy

We understand the challenges that arise when proposed strategies exceed budget constraints, forcing a reconsideration and exploration of alternative solutions. Our dedication is to finding the most cost-effective approaches.

Gain immediate, expert advice on streamlining projects to drastically cut down on administration time. Tranter combines small-company agility and customer focus, ensuring personalized attention to every customers needs.

At our core, we are deeply committed to not just meeting, but exceeding your expectations. We understand the importance of trust in any relationship, especially when it comes to the products you choose to bring into your applications.

Renewable energy

In biomass boilers and combined heat and power (CHP) plants, heat exchangers are used to transfer heat from the combustion of biomass fuels, such as wood chips or agricultural residues, to a heat transfer fluid, such as water or thermal oil. This heated fluid can then be used for space heating, water heating, or process heating in industrial applications.

Centralized solar power (CSP) plants use mirrors or lenses to concentrate sunlight onto a receiver, which heats a working fluid (such as molten salt). Tranter’s gasketed and welded plate heat exchangers transfer the heat from the working fluid to water, generating steam for electricity generation.

Geothermal power plants utilize heat exchangers to transfer heat from geothermal fluids (hot water or steam) extracted from underground reservoirs to a secondary working fluid, such as isobutane or refrigerants, that drives a turbine-generator. Heat exchangers ensure efficient heat transfer while preventing contamination of the working fluid by corrosive minerals or gases present in the geothermal fluid.

Wind power is becoming an essential part of the world’s renewable energy demand for the energy transition. Tranter’s plate heat exchangers are used in both onshore installations for lube oil, transmission and generator cooling, and for offshore wind installations for the HVDC platforms. Here, large gasketed plate and frame heat exchanger in titanium are deployed as Seawater/Cooling medium heat exchangers to cool down an ethylene glycol mix that will be used as cooling medium for other sensitive equipment on the offshore wind farm such as transformers and generators. Tranter’s heat exchangers play a key role in this process, enhancing efficiency and sustainability while not sacrificing on operational reliability for remote offshore installations.

To reach the NetZero goals, refineries are looking to reduce the CO2 emissions. Post combustion CO2 capture to refineries involves removing CO2 from gas streams using continuous absorption with regenerable solvents, crucial for reducing greenhouse gas emissions and fighting climate change. Tranter leads in providing heat exchangers for carbon capture, ensuring your plant operates safely and reliably.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Our comprehensive understanding of heat exchangers goes beyond just maintenance and usage. We offer tailored recommendations and innovative solutions to optimize your system's performance, reduce energy consumption, and extend the lifespan of your equipment. Our goal is to not only enhance your operational efficiency but also to ensure the long-term health and reliability of your heat exchangers. Trust Tranter to provide expert insights that keep your systems running smoothly and cost-effectively.

Resource center

Still curious?