Our most powerful product

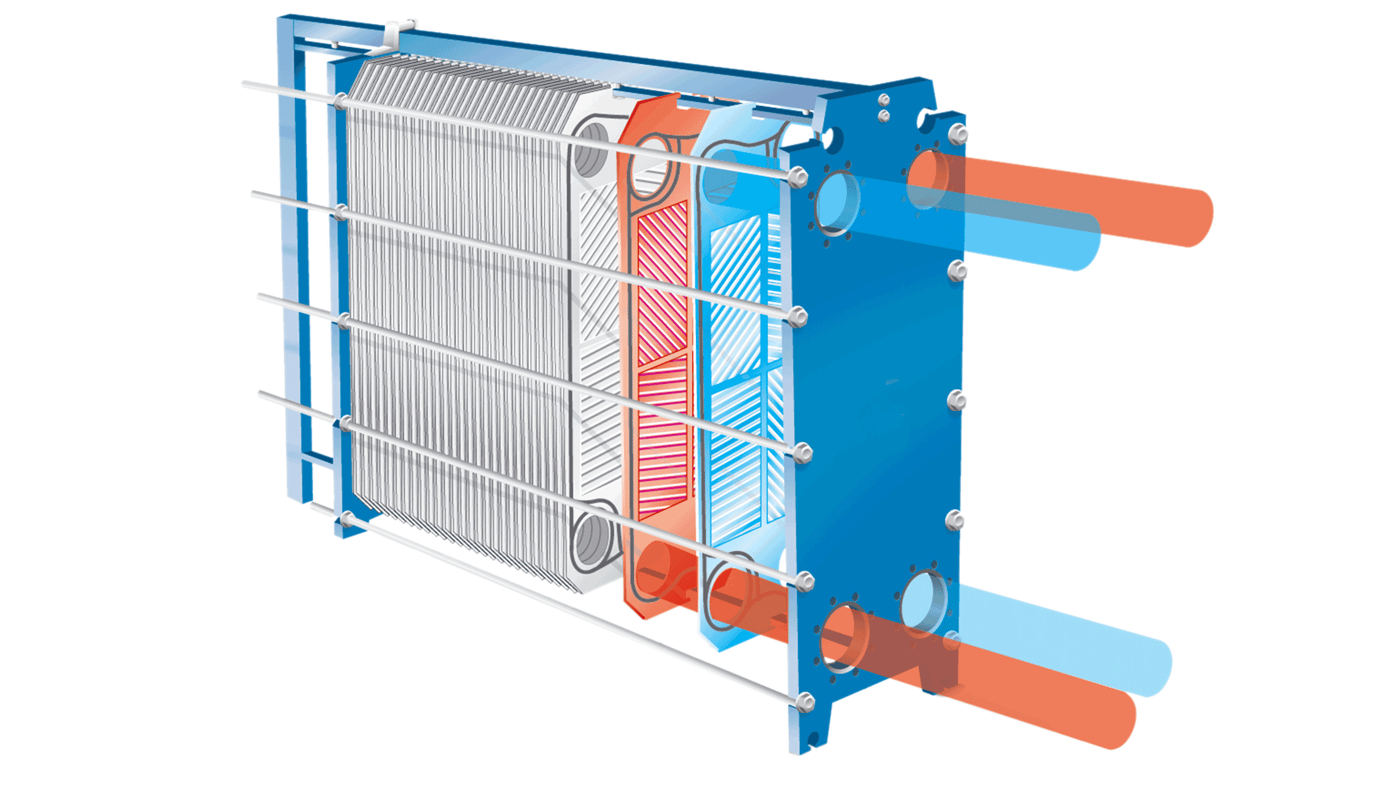

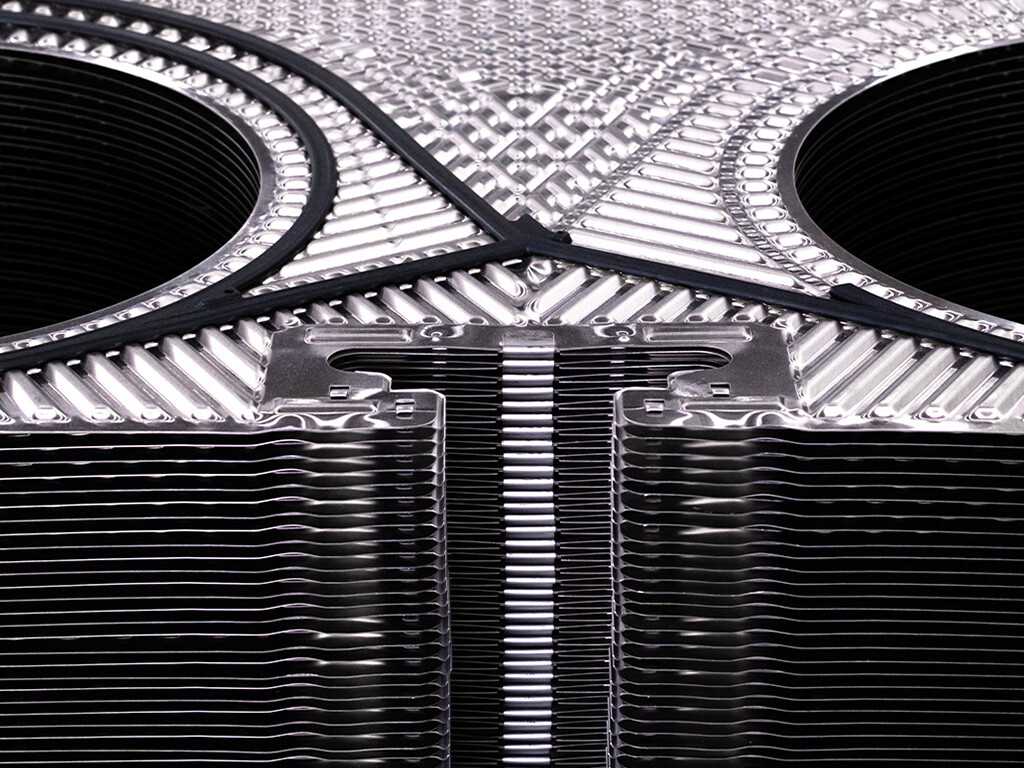

Gasketed plate and frame heat exchanger

Efficient and reliable heat transfer for every industry

Tranter Superchanger® Gasketed plate and frame heat exchanger

Astonishing endurance

Fit for performance

Astonishing endurance

Fit for strength

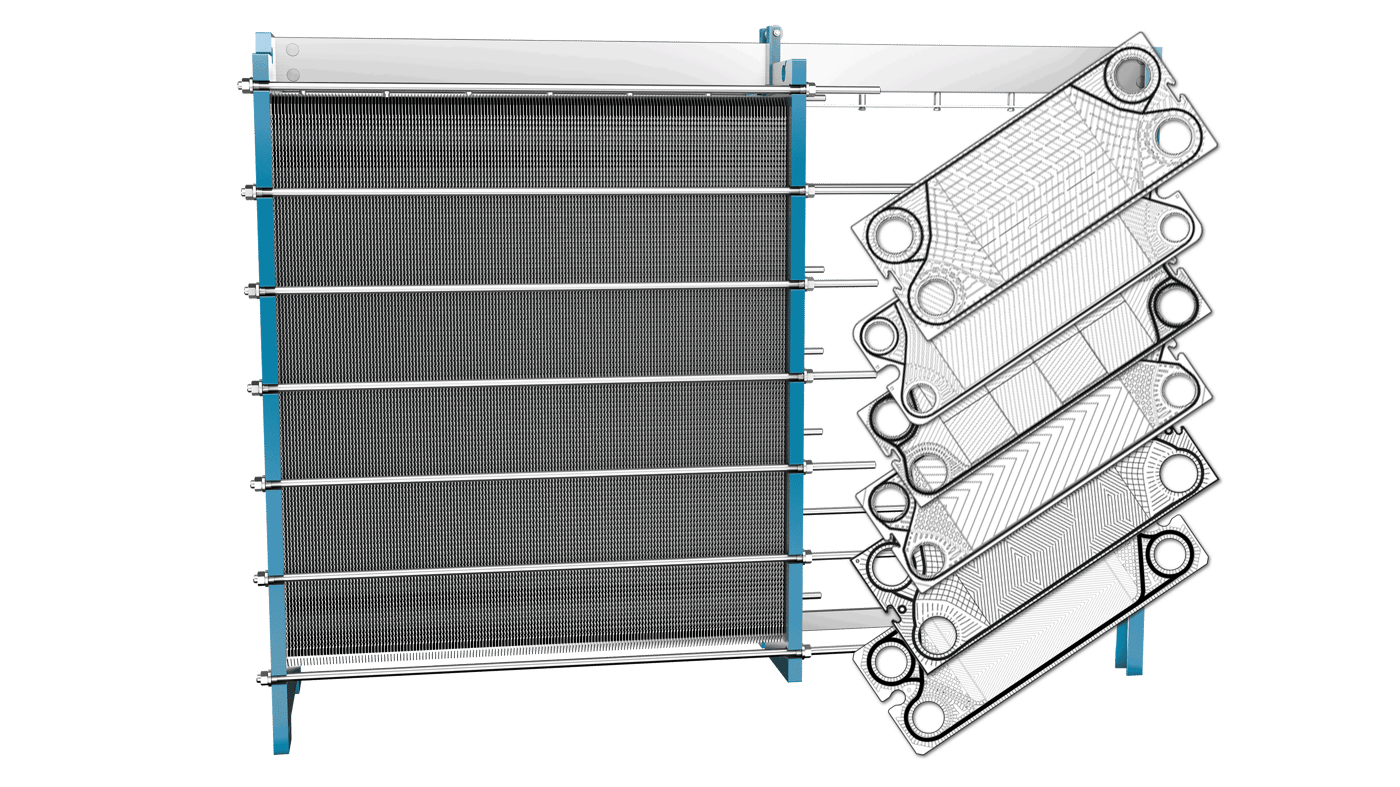

By using different types of plates, with different characteristics, the heat exchangers can be adapted to a wide variety of applications.

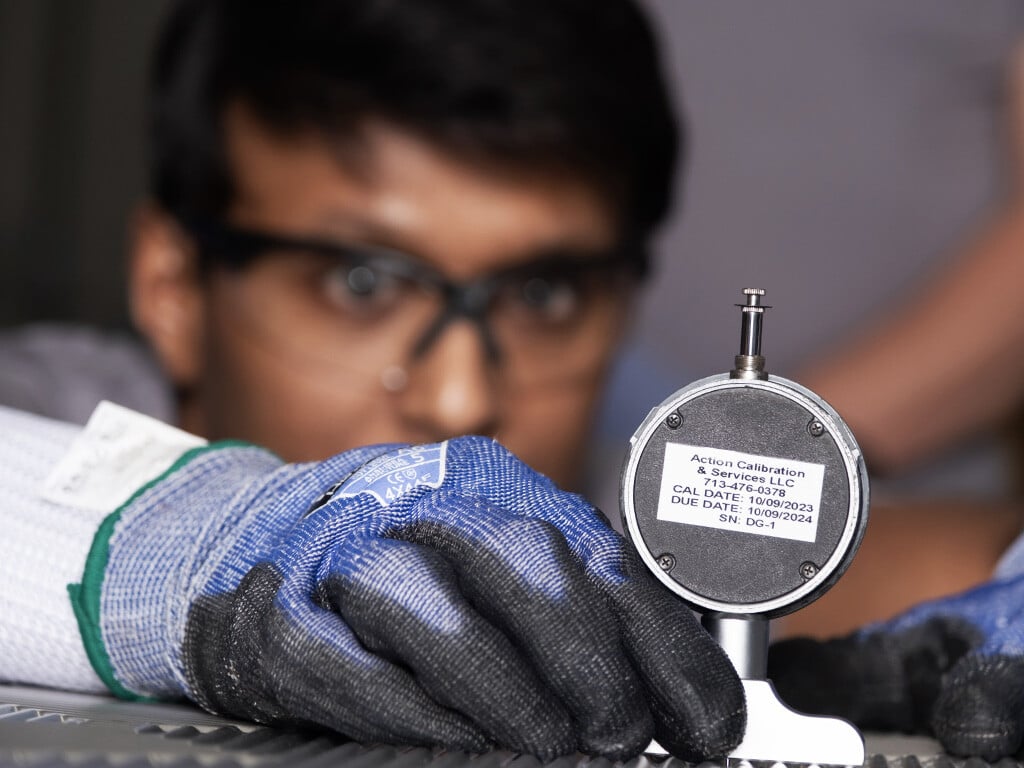

Astonishing endurance

Fit for service

Rigid plates and support hangers reduce plate assembly time resulting in a lower total cost of ownership for the unit. Lower your operating costs add to your profit margin with Tranter units on your team.

EFFICIENCY

Bringing efficiency to heat exchanger

Get efficient, cost-effective solutions with Tranter innovative heat exchanger technology.

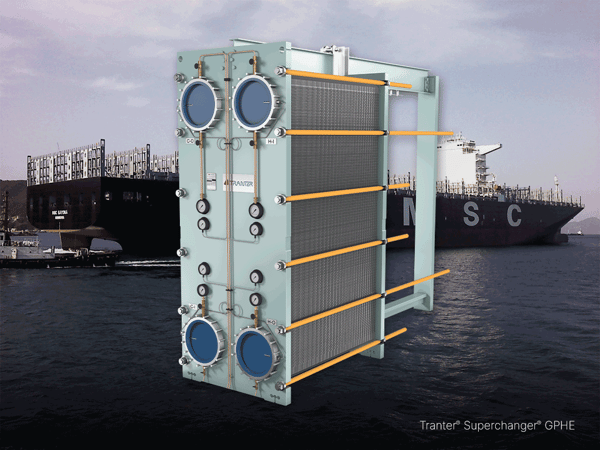

Wide spread of applications

Gasketed plate heat exchangers are at work worldwide, from the offshore oil platforms to the bustling rooftops of casinos and hospitals. They're the unseen backbone in chemical plants, refineries, gas processing facilities, and the cool server rooms of data centers, among others.

Advanced gasket/bleed port design

Plate range

Gasketed plate and frame heat exchanger

GT SERIES

- A deeper gasket groove for higher pressures.

- Our wide range of gasketed plate and frame heat exchangers enables customers to reduce energy consumption and the greater thermal efficiency of heat exchanger the more energy can be saved.

- Specially designed for close-temperature-approach applications found commonly in HVAC and petrochemical process industries.

GX SERIES

- Especially when flows are unbalanced and the allowable pressure drops are reasonably close.

- Our heat exchangers can be optimized for the characteristics for each individual application.

GC and GL SERIES

- Applications where low pressure drop is required or unit sizing is limited by pressure drop.

- This allows the flexibility to satisfy a wide range of applications.

GF SERIES

- Utilizing wide-gap plates economically recovers heat from waste streams in a variety of industries, including pulp and paper, sugar processing, alcohol production, grain processing, chemicals, textiles and ethanol distilling,etc.

- This series features wider gaps between plates. They're used extensively in the ethanol and pulp-and-paper industries and are perfect for applications where one or both streams have particulates that must pass through the heat exchanger.

GD SERIES

- This double-wall series is the ideal alternative where the two fluids on each side of the plates should not mix due to possible contamination or an undesirable reaction.

Resource center

Introducing ThermoFit™ DN150 plate series

Energy, Process industries Marine and shipbuilding Sustainability

Plate series introduction: The Omniflex™

Energy, Process industries Marine and shipbuilding Sustainability

Plate series introduction: The GT-165

resource center

Explore our latest guides and literature

Energy, heating and cooling Sustainability

Tranter heat exchangers in the sustainable data centers

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Heat exchangers for post combustion carbon capture applications

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter heat exchangers in green hydrogen production

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Sustainability Energy, heating and cooling Energy, Process industries

Bringing efficiency to heat transfer

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Parts and services

Restoring plate heat exchangers to optimal performance

With regular service and maintenance you will keep control of your heat exchangers conditions and maintain optimal performance. Learn more from this simplified quick guide.

Energy, heating and cooling Energy, Process industries Marine and shipbuilding

The Welded block heat exchanger - NovusBloc®

For increased durability and energy efficiency. Get some more insights to our welded block heat exchanger with this guide.

Energy, heating and cooling Energy, Process industries Marine and shipbuilding

When conditions are tough, think plates instead of tubes

Now you can obtain the thermal efficiency and compactness of gasketed heat exchangers in elevated pressure/high-and-low temperature applications. Learn more about our shell and plate heat exchanger.

Energy, heating and cooling Energy, Process industries Sustainability

Plate and frame for maximum efficiency

Optimum performance is a promise Tranter has been fulfilling for many decades with the Superchanger® plate and frame heat exchanger.

Energy, heating and cooling

Guide: Selecting the right heat exchanger for your heating and cooling application

Selecting a heat exchanger is not just about finding an option that fits within your budget. Your choice should strike an optimal balance between cost and performance. Otherwise, you could end up with a unit that’s not designed for its purpose. This mistake can be costly. So, how do you know which exchanger is right for you?

Parts and services

Guide: 8 steps to improve (and maintain) heat exchanger efficiency

Are you tired of feeling like your heat exchanger is draining your wallet like a car engine left running all night? Our guide walks you through the steps you need to take – from pre-purchase and design to maintenance – to get the most out of your heat exchanger.

Innovation and development

Resource center

Discover our customer cases

Energy, Heating and cooling

Tranter China joins hands with Jinmao to create a new model of sustainability

Marine and shipbuilding

Daewoo opts for Tranter’s plate heat exchangers for world’s biggest container ships

TRANTER FULLSERV® – Full support for every brand

Are you considering acquiring heat exchangers?

Contact us for more information!