Resisting aggressive media

Tranter’s solutions are highly customizable and can come in a vast range of corrosion-resistant materials that extend lifetime in chemical-rich environments.

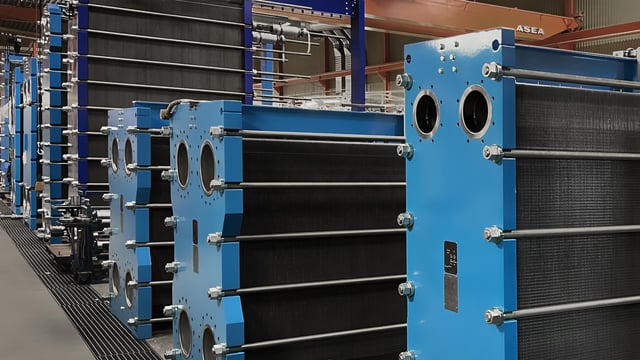

Improve efficiency with Tranter heat exchangers

Petrochemical production is unforgiving. Aggressive chemicals attack your equipment and fouling cuts uptime, all while the energy demand is relentless. At the same time, plants must stay compliant and deliver the output the market depends on.

Tranter heat exchangers are engineered to actually thrive in these conditions. Our solutions help you protect assets, recover energy, and keep your plant running reliably day after day.

Petrochemicals and chemicals

Tranter’s solutions are highly customizable and can come in a vast range of corrosion-resistant materials that extend lifetime in chemical-rich environments.

Petrochemical processes are energy-hungry. Recover more waste heat from cracking, reforming, and cooling to lower fuel use and emissions.

Fouling-resistant plate geometries extend cleaning intervals and keep production stable.

Space is always at a premium. Tranter’s compact exchangers simplify retrofits and save space in crowded plants.

Heat exchangers designed to meet ASME, API, EN, and ISO standards for compliance and safety.

From FEED to field service. Tranter provides engineering expertise, spare parts, and rapid global response.

Petrochemicals and chemicals

Running EO/EG plants means walking a fine line: aggressive process conditions, high energy demand, and the need to stay aligned with licenser specs.

Tranter’s heat exchangers:

As two of the most widely produced polymers, PE and PP require precise and efficient heat transfer at every stage. And when every ton of polymer counts, you can’t afford thermal instability.

Our solutions enable:

Petrochemicals and chemicals

Benzene, toluene, and xylene production pushes exchangers to their limits.

Tranter units recover more heat and resist fouling, helping you lower energy intensity and keep output steady.

Aggressive media, continuous duty, and safety compliance are non-negotiable.

Our corrosion-resistant designs give you durability and peace of mind in critical processes.

Product quality depends on tight thermal control.

Tranter exchangers deliver stable cooling and heating through polymerization and extrusion, minimizing downtime and off-spec production.

In mills, both processes and utilities keep the plant alive. Our exchangers improve efficiency in steam loops, cooling water, and effluent treatment, reducing overhead while boosting reliability.

Why Tranter

We have solved your challenges before, proven by references in major petrochemicals projects worldwide.

90+ years of heat exchanger engineering and manufacturing expertise.

Parts and technicians where you need them, backed by centralized QA.

Configured for the unique efficiency and durability demands of the petrochemical industry.

Our R&D focuses on what matters most in oil and gas: plate designs that handle higher pressures, compact layouts for space-constrained sites, and alloys built for aggressive media.

This means higher efficiency and solutions that help you hit both production and sustainability targets.

With Tranter FullServ®, you get lifecycle support for every brand of heat exchangers. We keep your equipment running, from inspection and reconditioning to emergency on-site service.

Our rapid-response teams and local service centers around the world ensure your exchangers deliver peak performance longer.

Cutting CO₂ without cutting output is one of the toughest challenges in petrochemicals. Carbon capture and green hydrogen projects demand exchangers that can handle aggressive solvents and tight energy balances.

Tranter provides solutions for the critical CCUS and hydrogen positions, from lean/rich interchangers to CO₂ coolers. Compact, durable, and fouling-resistant, they help you reduce energy use and integrate cleanly into both retrofits and new builds.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Resource center

Still curious?