Corrosion resistance where it counts

Tranter uses marine-grade materials and plate designs proven offshore, extending run time and cutting replacement costs.

Improve efficiency with Tranter heat exchangers

Offshore support vessels work where seas are harsh and contracts depend on staying ready. A failed heat exchanger offshore means lost efficiency and business.

Tranter exchangers are built marine-tough, with compact designs and corrosion-resistant materials. Backed by a global supply chain and service features that keep your engines running and compliant even in the most demanding offshore environments.

Offshore support vessels

Tranter uses marine-grade materials and plate designs proven offshore, extending run time and cutting replacement costs.

Every ton matters on offshore modules. Our heat exchangers deliver full capacity in smaller, lighter frames that fit crowded machinery rooms and deck skids.

Anchor handling, supply, standby — OSVs never sit idle. Tranter exchangers are built to resist vibration and pressure swings without performance loss.

.png?width=640&height=360&name=Collage%20Marine-v2%20(1).png)

From seawater cooling loops to glycol systems, our plate patterns keep heat transfer stable across varied fluid duties, improving uptime and cutting energy demand.

Frames that open fast and service-friendly layouts mean cleaning and inspections take hours, not entire shifts.

Wherever your vessel docks, Tranter OEM service and parts are within reach, so downtime offshore doesn’t become downtime onshore as well.

Offshore support vessels

Meeting IMO rules offshore is non-negotiable. Tranter exchangers keep clean-fuel systems safe and stable without sacrificing efficiency.

Heavy-duty marine engines generate extreme heat. Our exchangers dissipate it effectively, protecting engines from damage and avoiding costly offshore downtime.

Reliable lube oil cooling keeps machinery safe during nonstop operations, extending service life and reducing overhaul frequency.

Why Tranter

Tranter heat exchangers are already installed in offshore vessels worldwide.

90+ years of heat exchanger design and thermal engineering knowledge.

Service centers and supply chain support where and when you need them.

Configured for the unique efficiency and durability demands of offshore vessels.

Every offshore mission is different, which means exchangers can’t be “one size fits all.” Our goal is to support OSV operators with more uptime between service calls and vessels ready to take on the next mission.

With Tranter FullServ®, you get lifecycle support for every brand of heat exchangers. We keep your equipment running, from inspection and reconditioning to emergency on-site service.

Our rapid-response teams and local service centers around the world ensure your exchangers deliver peak performance longer.

Resource center

Parts and services

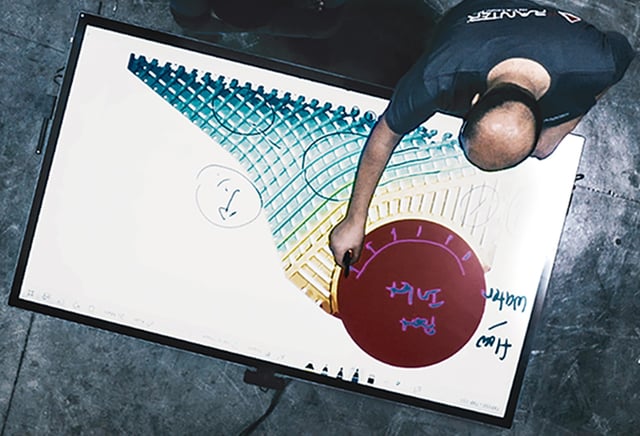

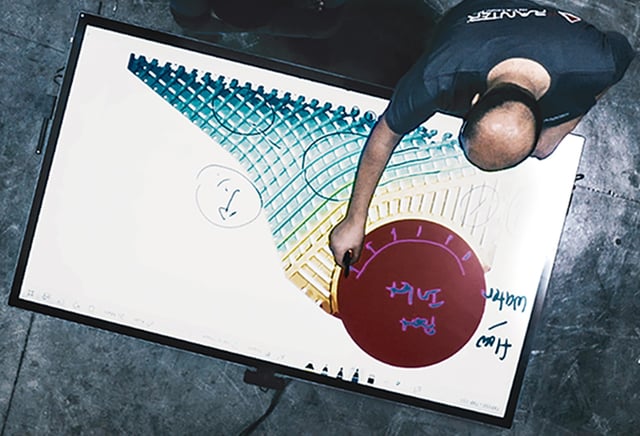

When it comes to inspection and plate removal, it's crucial to pay attention to every detail. By following the necessary steps and taking the time to inspect and remove plates properly, we can ensure that your project is completed successfully. Learn more by listening to Dave Lusignolo, Director, Aftermarket Sales - North America

Parts and services

Chemical cleaning and rinse are essential steps in maintaining the performance of your heat exchanger. Whether it's removing liquids, or ensuring the longevity of machinery, chemical cleaning and rinse play a crucial role in the service process.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Resource center

Still curious?