Handling aggressive media

Advanced materials and plate designs resist corrosive solvents used in carbon capture and P2X, keeping your systems stable.

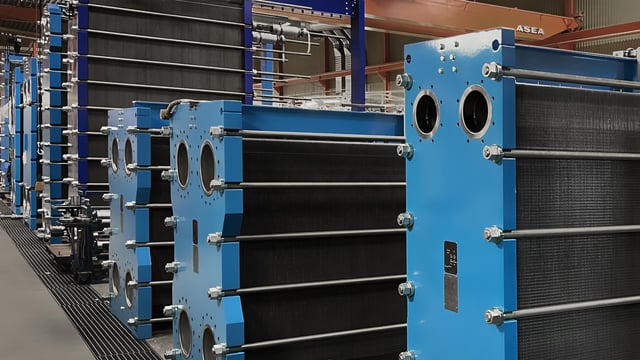

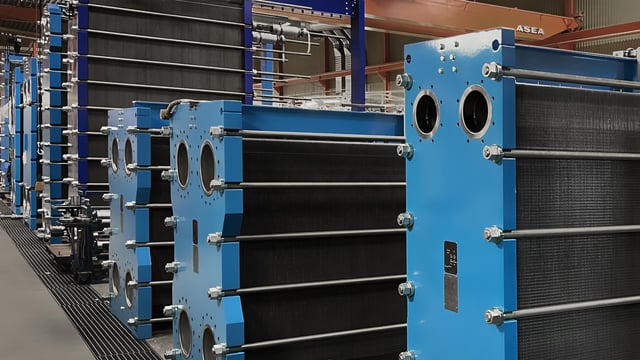

Improve energy efficiency with Tranter heat exchangers

Whether you’re scaling carbon capture, producing green hydrogen, or integrating Power-to-X, the challenges are the same: aggressive solvents, tight footprints, extreme duty cycles, and relentless pressure to cut costs while proving sustainability.

Tranter helps you meet those challenges with heat exchangers designed for the realities of the energy transition. With our solutions, you can move from ambitious plans to reliable, long-term performance.

Energy transition

Advanced materials and plate designs resist corrosive solvents used in carbon capture and P2X, keeping your systems stable.

Our solutions are built for optimal waste heat recovery across hydrogen electrolysis, fuel cells, storage systems, and tight temperature programs.

Compact exchangers integrate seamlessly into skids, offshore platforms, and retrofit plants where every square meter counts.

Fouling-resistant plate geometries and service-friendly frames extend cleaning intervals and minimize downtime in continuous-duty environments.

From pre-FEED studies to commissioning, Tranter supports your project with licenser alignment, proven references, and rapid service and parts delivery worldwide.

Energy transition

Scaling carbon capture is about building bigger plants and running them reliably. Corrosive solvents, nonstop operation, and efficiency targets leave no margin for error. With us, you can:

Electrolysis is the backbone of hydrogen production, but thermal management determines whether it’s efficient and scalable. Here’s how Tranter makes a difference:

Energy transition

Grid stability depends on storage. Tranter exchangers make large-scale thermal storage more efficient, helping you integrate renewables and improve resilience.

Fuel cells rely on precise temperature and water control to perform. Our exchangers keep stacks balanced, boosting output and extending service life.

Turning renewable energy into fuels like e-methanol or e-ammonia is energy-intensive.

Tranter exchangers improve heat recovery and efficiency, making P2X more economically viable at scale.

Why Tranter

References across carbon capture, hydrogen, and P2X plants.

90+ years of heat exchanger design, adapted to tomorrow’s energy challenges.

Local service centers and spare parts where and when you need them.

Our heat exchangers are configured to the unique realities of transition technologies.

The energy transition is evolving fast. That’s why Tranter’s R&D focuses on innovations that matter to you: advanced materials for harsh solvents, compact layouts for space-constrained plants, and designs that recover more waste heat.

These advances help you reduce lifecycle costs, cut emissions, and bring sustainable energy projects online faster.

With Tranter FullServ®, you get lifecycle support for every heat exchanger brand. We keep your equipment running, from inspection and reconditioning to emergency on-site service.

Our rapid-response teams and local service centers around the world ensure your exchangers deliver peak performance longer.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

resource center

Still curious?