Heat exchangers designed for long-lasting performance

- Service for every brand of plate heat exchangers

- Providing fast and customized solutions to meet all regional requirements

Customized solutions designed for your needs

At Tranter, we specialize in advanced gasketed and welded plate heat exchangers. As a global manufacturer, we are committed to precision and localized service across key regions worldwide. From HVAC systems to oil and gas processing, our extensive product range meets the most demanding industrial applications.

Specializing in gasketed and welded plate heat exchangers.

Committed to quality, efficiency, and sustainability.

Service leadership

Explore

Global support for the following industries

Energy process industries

High-efficiency heat exchangers designed for the rigorous demands of processing industries.

Energy heating and cooling

Custom solutions for heating, ventilation, and air conditioning in commercial buildings.

Marine and shipbuilding

Specialized products that meet the unique requirements of maritime environments.

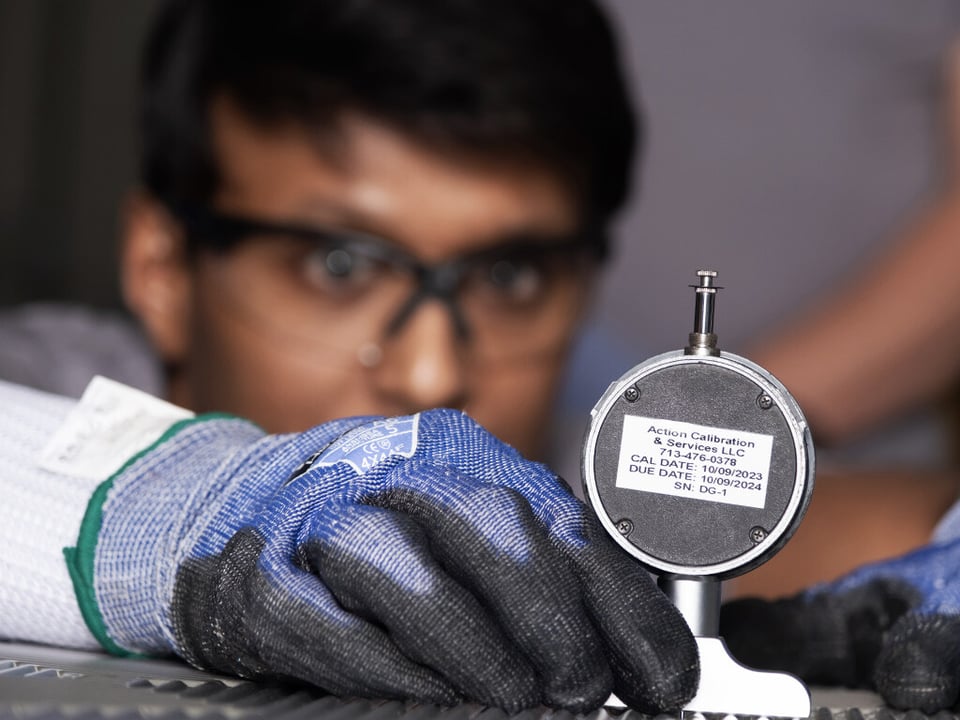

Service for every brand

Our strategic locations worldwide ensure quick, efficient service and maintenance, supporting all brands of heat exchangers.

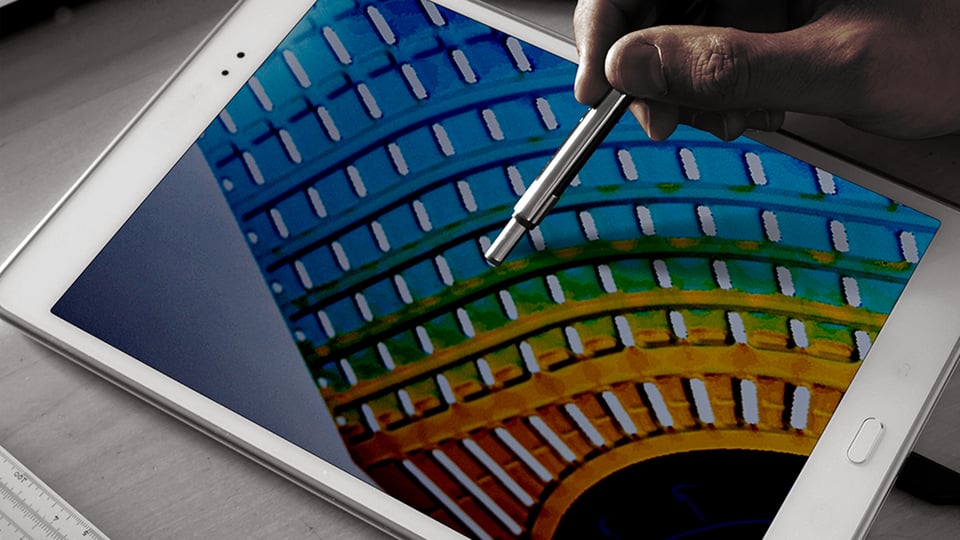

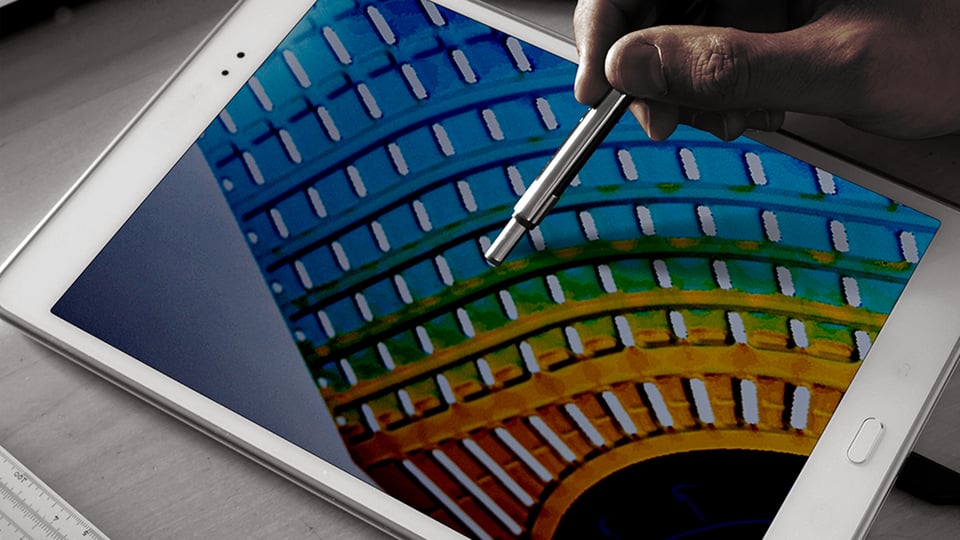

Innovation and product development

At the core of Tranter's progress is our Research & Development (R&D) department, committed to advancing heat exchanger technology.

Our heat exchangers

More than just heat exchangers, we call them solutions

Resource center

Explore the latest articles from Tranter

Still interested?

Contact Tranter worldwide