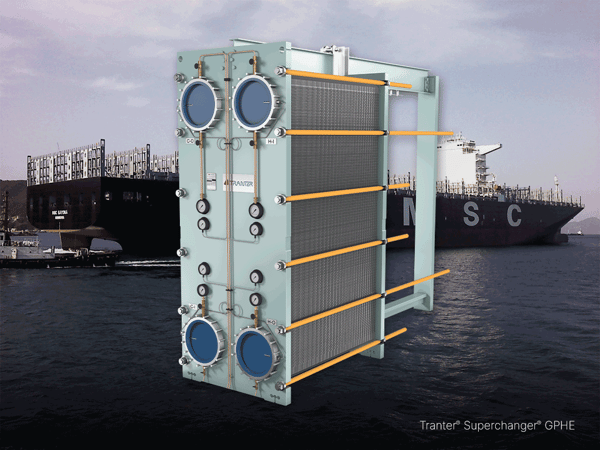

Wide range of applications

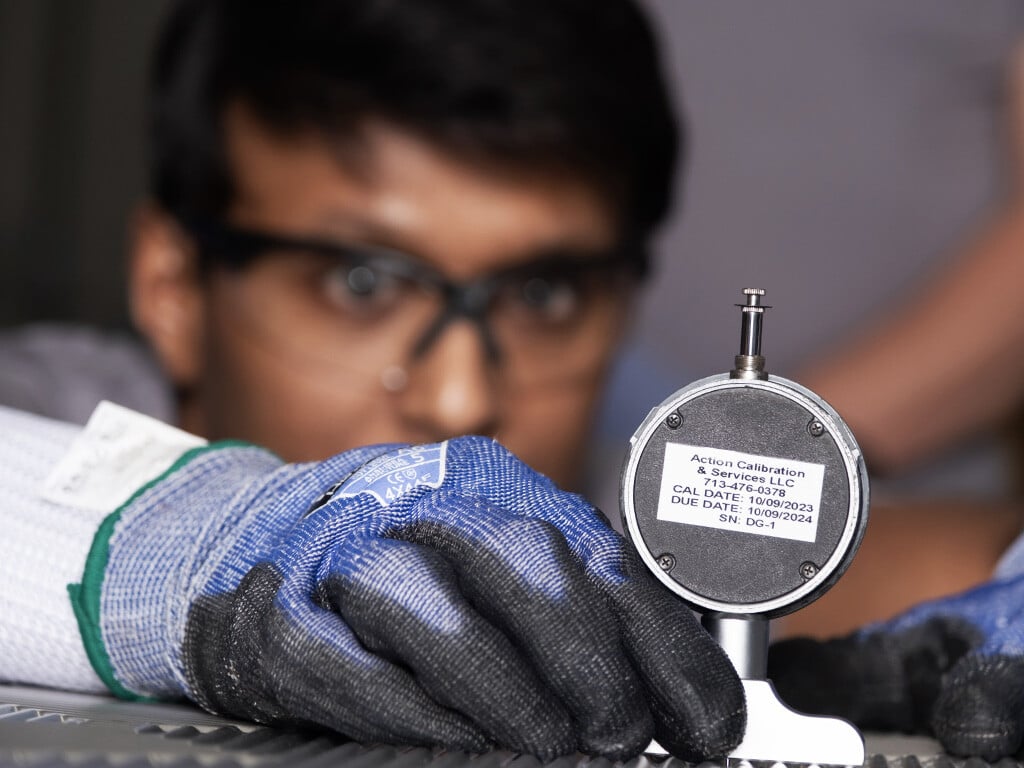

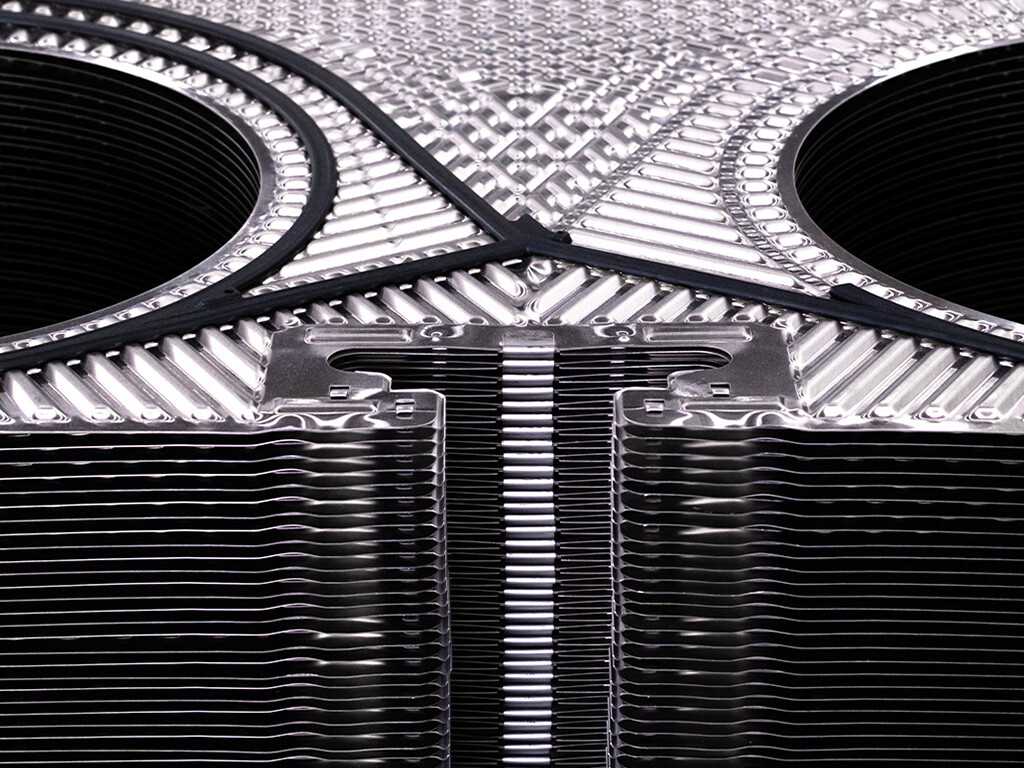

Through rigorous testing for heat transfer, pressure, and temperature fatigue, the NovusBloc® has proven its remarkable ability to offer a more compact, lighter, and efficient design while enhancing durability for diverse applications.