Ensure product quality

Heat-sensitive lines suffer when temperatures drift. Our exchangers hold tight approach temperatures, keeping batches consistent and scrap down.

Manufacturing, Machinery, and General Industry

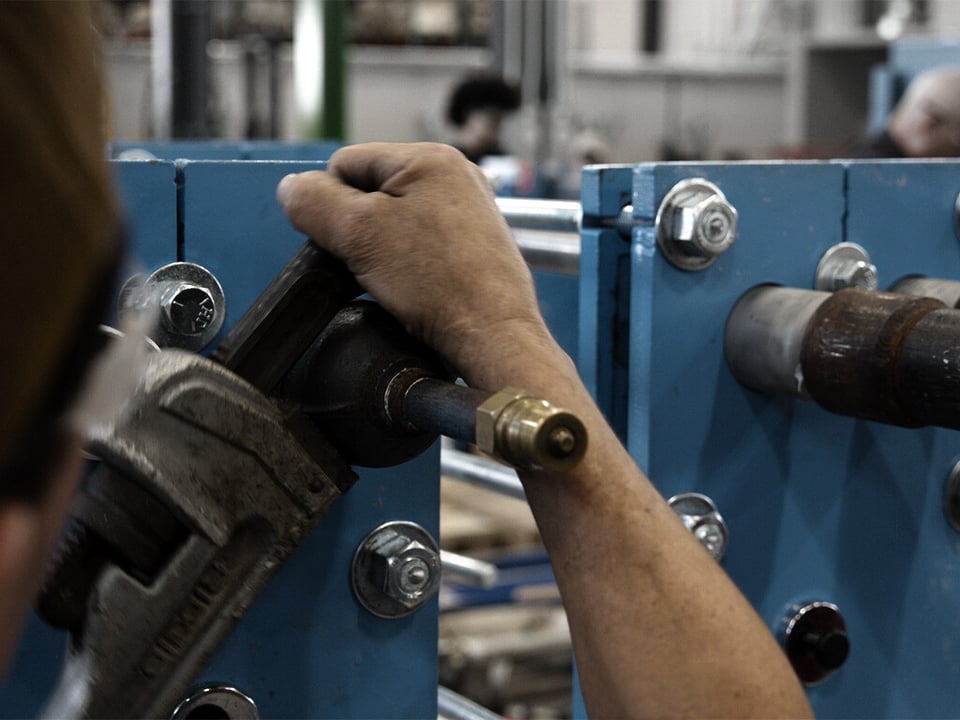

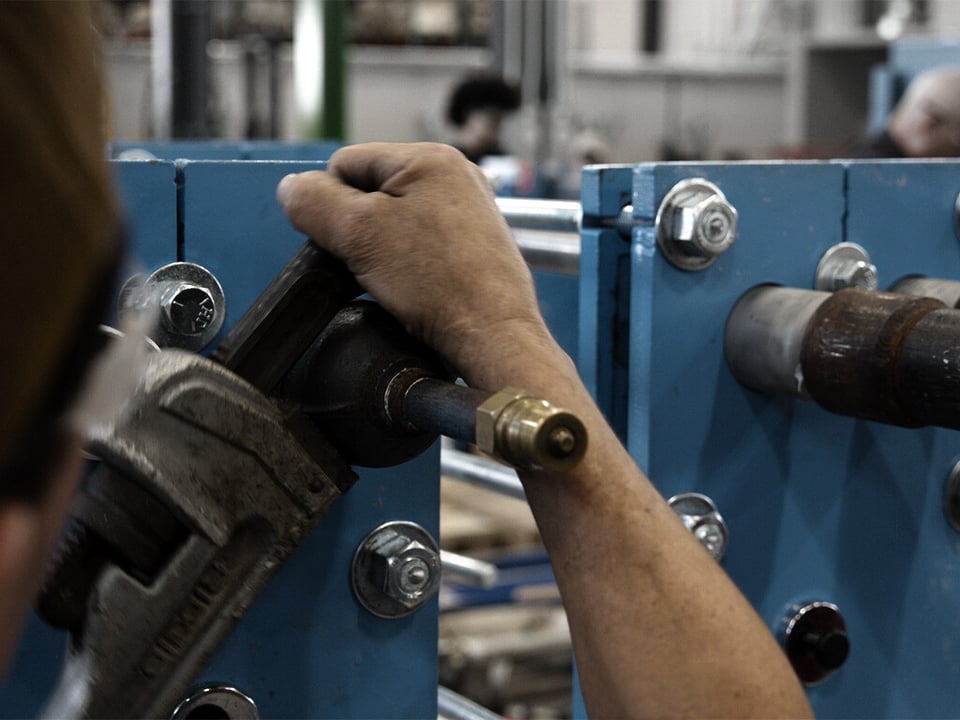

In manufacturing, temperature control makes or breaks the day. If cooling slips, machines overheat. If heating isn’t stable, you lose batches. And every extra kilowatt wasted hits your margins.

That’s why so many plants lean on Tranter. Our plate heat exchangers are efficient and tough enough for real industrial duty. They keep your lines running and products consistent, and your energy bills under control.

In manufacturing, every heat exchanger variable shows up in uptime, energy bills, product quality, and crowded spaces.

With Tranter, you get equipment built to keep your processes steady and efficient.

Manufacturing and machinery

Heat-sensitive lines suffer when temperatures drift. Our exchangers hold tight approach temperatures, keeping batches consistent and scrap down.

We design to your load profile, water quality, and cleaning cycles, so performance always holds up to the spec sheet — at minimum.

High pressure drop robs pumps and budgets. We restore headroom with flow paths that keep ΔP in check while maintaining the thermal approach you need.

Opening, cleaning, and reassembly shouldn’t take a day. Quick-open frames and clear access points cut service time and operator burden.

Manufacturing and machinery

From stamping presses to paint lines, automotive plants run hot and heavy. Tranter heat exchangers help you manage coolant, process water, and lube oil reliably with designs that meet the industry’s strict standards.

Hydraulic circuits and lube oil systems demand stable cooling without adding pressure drop.

Our plate exchangers are flexible enough for small or high flow duties, and in turbomachinery we can even supply complete lube oil cooler skids for compressors and rotating equipment.

Pressing, cutting, and shaping metals puts serious strain on both equipment and lubrication systems. Tranter exchangers provide precise thermal control for heating and cooling metals, while keeping lube oil stable and safe.

Compressors are the heartbeat of many industrial systems, from ORC to refrigeration. Tranter exchangers keep them healthy by cooling and condensing process fluids while stabilizing lube oil. The result: longer compressor life and more reliable performance.

Engines can’t afford to run too hot. Our compact plate-and-frame exchangers control jacket water and coolant temperatures directly on the engine, preventing overheating and ensuring reliable, long-term performance.

Why Tranter

Our exchangers are installed in manufacturing plants worldwide.

90+ years of heat exchanger design and thermal engineering knowledge.

Service centers and supply chain support where and when you need them.

Configured for the unique efficiency and durability demands of manufacturing.

Tranter’s R&D is aimed squarely at the realities of industrial plants. We develop plate patterns that foul less, frames that adapt to skids and retrofits, and materials that hold up against aggressive fluids. Even service is re-engineered with quick-open designs that cut cleaning time.

With Tranter FullServ®, you get lifecycle support for every brand of heat exchangers. We keep your equipment running, from inspection and reconditioning to emergency on-site service.

Our rapid-response teams and local service centers around the world ensure your exchangers deliver peak performance longer.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Resource center

Energy, Process industries Marine and shipbuilding Sustainability

Energy, Process industries Marine and shipbuilding Sustainability

Resource center

Still curious?