Communication

Gain immediate, expert advice on streamlining projects to drastically cut down on administration time. Tranter combines small-company agility and customer focus, ensuring personalized attention to every customer's needs.

Elevate the energy efficiency

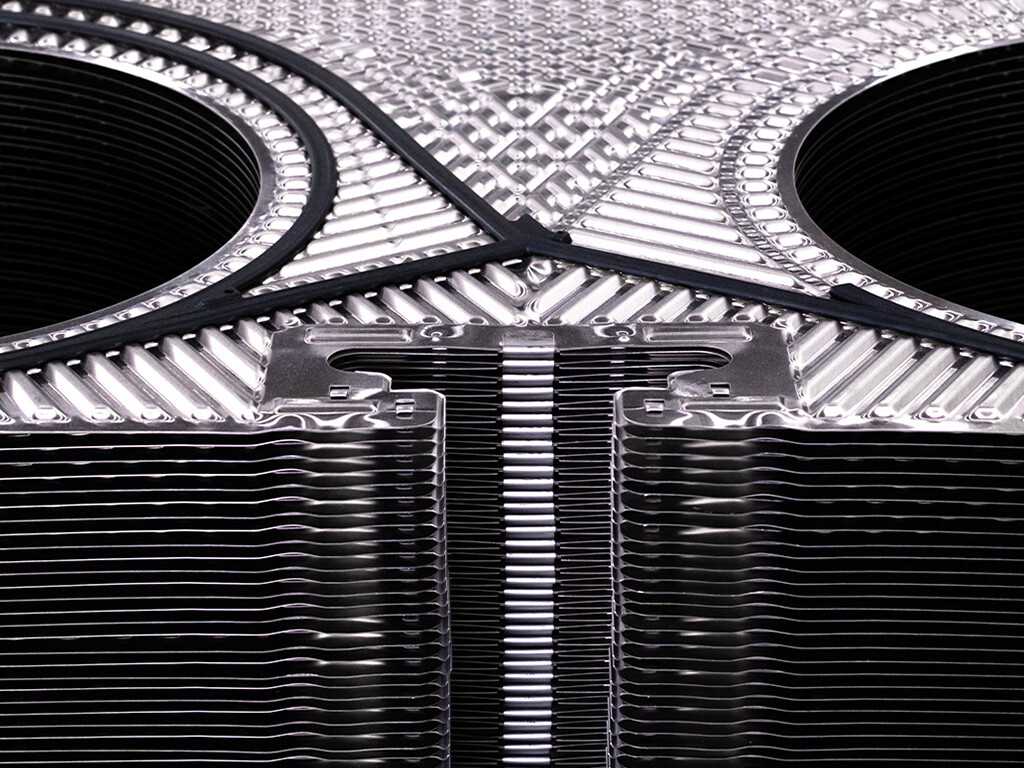

Tranter’s gasketed and welded plate heat exchangers are designed and proven to endure the challenges of corrosive and erosive substances, mixed-phase fluids, as well as the high pressure and temperature seen in oil and gas processing applications. Our offerings are specially designed for the oil and gas sector, enhancing processes like crude oil stabilization and desalting, produced water cooling, hydrocarbon gas dehydration and gas sweetening – all aimed at boosting process efficiency, elevating product quality without sacrificing reliability. Our customers include leading oil and gas companies such as Shell, ExxonMobil, British Petroleum, Chevron, Equinor, Petrobras and TOTAL.

Oil and gas industry

Gain immediate, expert advice on streamlining projects to drastically cut down on administration time. Tranter combines small-company agility and customer focus, ensuring personalized attention to every customer's needs.

We know how to navigate the challenging terrain of embracing new, yet possibly untested, technologies while ensuring processes remain dependable and steady.

Evaluating suppliers demands and deep dive into data for a thorough analysis can be hard. We assist in securing fast and comprehensive support, streamlining the decision-making process.

Oil and gas industry

In offshore oil and gas processing on offshore platforms or on the top sides of an FPSO, reliability, maintainability, space and weight savings are all essential for the operation. Tranter’s plate heat exchangers are proven designs in offshore crude oil stabilization trains, water and gas treatment modules, reducing downtime and the total cost of ownership.

Gas treatment is crucial in the oil and gas industry, ensuring natural gas meets quality, compliance, and safety standards for consumer use or further processing. Our gasketed and welded plate heat exchangers are successfully deployed in gas sweetening, gas dehydration skids, and gas compression trains, providing high efficiency and reliability in operation.

Oil and gas industry

In the crude oil stabilization process, Tranter’s gasketed plate and frame heat exchangers in titanium are used to pre-heat the crude oil for the desalting, as well as recover the heat from the heating medium introduced into the system, and finally to cool the desalted crude oil prior to storage. Our plate heat exchangers are also well suited for cooling the high salinity produced water from the desalter. Small footprint, and easy maintenance of the plate heat exchangers in crude service are essential.

Natural gas dehydration is the process of removing associated water from the wet gas stream. Dehydration of natural gas is essential to avoid methane hydrate formation which can plug valves and other equipment downstream, and condensed water in gas pipelines that can cause corrosion and restricted flow. Tranter’s gasketed and welded plate heat exchangers are employed in TEG dehydration skids in heat recovery, cooling and overhead condensing of the TEG. Our designs are efficient and compact, making them perfect for gas dehydration skids where available space and weight are limited.

Natural gas sweetening or acid gas removal is the process of removing acidic gases such as hydrogen sulfide, carbon dioxide and mercaptans to make the gas suitable for transport, storage and sale. Gas sweetening is commonly done by amine absorption, where Tranter’s gasketed and welded plate heat exchangers are used as heat recovery in the lean/rich amine interchanger/pre-heater to reduce the amount of steam needed for the reboiler, improving the total economy of the plant. Our heat exchangers also provide excellent temperature control as lean amine coolers, thermosyphon reboilers and stripper overhead condensers.

Natural gas and separated gases from the crude oil stabilization need to be compressed for storage, pipeline transportation or other use. As natural gas is compressed heat is generated that must be dissipated to cool the gas stream, and liquids from wet gases need to be condensed and separated. Tranter’s shell & plate heat exchangers offer many benefits as gas compression inter coolers, after coolers and vapor recovery units over traditional shell and tubes or printed circuit heat exchangers. Highly efficient plate technology results in smaller footprint, lower weight and less fouling tendencies compared to shell and tubes, and the shell and plate heat exchangers offers significant OPEX and CAPEX savings compared to printed circuit heat exchangers that easily clogs from compressor oil carry-over. Tranter’s gasketed plate and frame heat exchangers are employed for compressor lubrication oil cooling on the compressor skids or compressor stations, providing compact footprint and trouble-free operation.

A closed loop of cooling medium, normally water or water/glycol mixture is used for all the different cooling duties in oil and gas processing plants. The cooling medium is cooled by seawater in gasketed plate and frame heat exchangers to avoid using corrosive and erosive seawater inside the process. Tranter’s plate and frame heat exchangers are optimal for large cooling medium cooler duties, capable of handling close temperature approaches and large volumes with minimum plot space requirements.

Our comprehensive understanding of heat exchangers goes beyond just maintenance and usage. We offer tailored recommendations and innovative solutions to optimize your system's performance, reduce energy consumption, and extend the lifespan of your equipment. Our goal is to not only enhance your operational efficiency but also to ensure the long-term health and reliability of your heat exchangers. Trust Tranter to provide expert insights that keep your systems running smoothly and cost-effectively.

Resource center

Parts and services

When it comes to inspection and plate removal, it is crucial to pay attention to every detail. By following the necessary steps and taking the time to inspect and remove plates properly, we can ensure that your project is completed successfully. Learn more by listening to Dave Lusignolo, Director, Aftermarket Sales - North America

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Resource center

Still curious?