Verified performance

With AHRI-certified exchangers, the cooling capacity you buy is the cooling capacity you get. Every unit delivers the thermal output promised.

Boosting data center performance

In data centers, “good enough” cooling isn’t good enough. Servers generate massive heat 24/7 and uptime contracts leave zero margin for error. Even a few minutes of failure can cost millions in penalties, lost business, and reputation.

That’s why your cooling systems need exchangers you can trust. Verified performance, purpose-built designs, and OEM service that keeps you ahead of failures, so that your facility runs efficiently and without surprises.

Data centers

With AHRI-certified exchangers, the cooling capacity you buy is the cooling capacity you get. Every unit delivers the thermal output promised.

Our AT Series plates are engineered for high-density IT loads, delivering more thermal performance with less surface area.

Tranter heat exchangers cut pumping energy, reduce chiller load, and enable free cooling to improve PUE, WUE, CUE, and ERE.

Predictive and prescriptive service pinpoints which unit needs attention and when, avoiding unnecessary downtime.

We work with you and your partners to value-engineer exchangers that balance cost, reliability, and sustainability.

OEM expertise, troubleshooting, and service teams that solve your problems even beyond the exchanger itself.

Data centers

Keep IT equipment cool with exchangers linking chillers to towers or free-cooling sources. Protect against fouling, cut system costs, and bypass chillers when ambient conditions allow, even while driving PUE, WUE, CUE, and ERE improvements.

As direct liquid cooling expands, compact exchangers in coolant distribution units (CDUs) keep rack-level cooling stable and integrate seamlessly with towers and free-cooling sources.

Regulate air temperature and humidity across server halls, keeping conditions within strict operating ranges around the clock.

Why Tranter

Our heat exchangers already run in conventional, hybrid, and liquid-cooled data centers worldwide.

90+ years of heat exchanger design and thermal engineering knowledge.

Service centers and supply chain support where and when you need them.

Configured for the unique efficiency and durability demands of data centers.

Data centers are evolving fast, from liquid cooling adoption to heat reuse and renewable integration.

Our R&D is focused on what matters most to you: compact designs for high-density racks, materials that last in treated water systems, and smarter service tools that keep cooling infrastructure reliable. The result? Less energy, less risk, and more confidence as you scale.

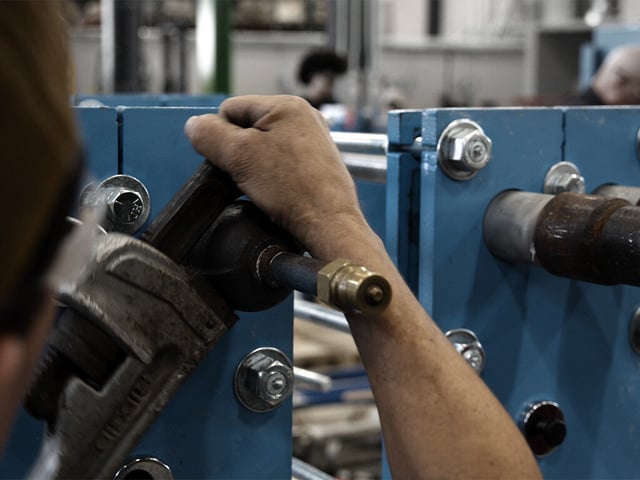

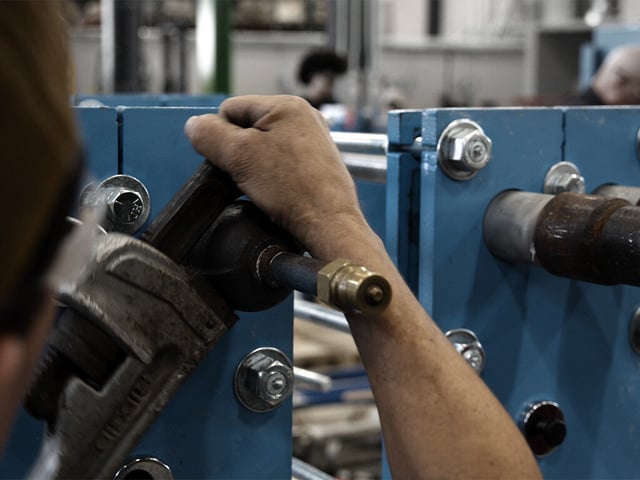

With Tranter FullServ®, you get lifecycle support for every brand of heat exchangers. We keep your equipment running, from inspection and reconditioning to emergency on-site service.

Our rapid-response teams and local service centers around the world ensure your exchangers deliver peak performance longer.

Resource center

Resource center

Energy, Process industries Marine and shipbuilding Sustainability

Energy, Process industries Marine and shipbuilding Sustainability

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Still curious?