On time deliveries

We understand how critical it is for our customers to meet or even surpass project timelines. It's for this reason we are committed to ensuring deliveries are not just on time, but guaranteed to be prompt.

Enhancing HVAC efficiency and innovation

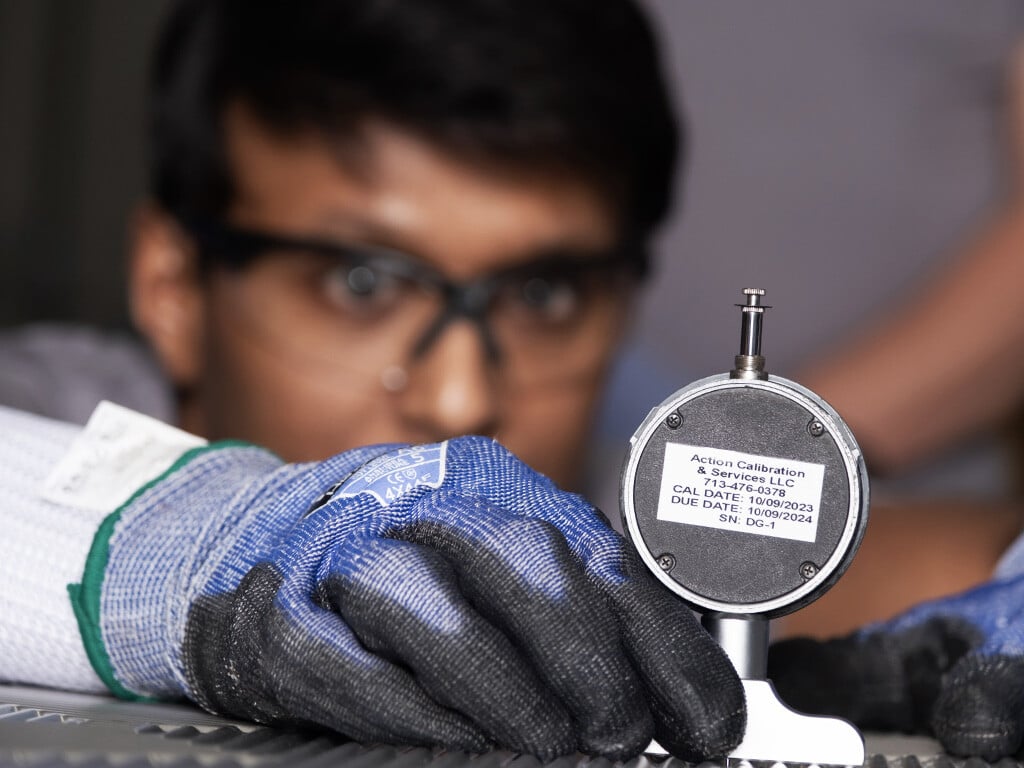

Mastering the complexities of plate heat exchangers is not just about understanding their operational nuances but also ensuring they align perfectly with your heating and cooling system’s needs. We create customized solutions for heating, ventilation, and air conditioning in commercial buildings.

HVAC heating and cooling

We understand how critical it is for our customers to meet or even surpass project timelines. It's for this reason we are committed to ensuring deliveries are not just on time, but guaranteed to be prompt.

Minimize your project expenses effectively by implementing strategic cost-saving measures. Adopting efficient planning, and ongoing cost analysis can dramatically reduce unnecessary expenditures.

Gain immediate, expert advice on streamlining projects to drastically cut down on administration time. Tranter combines small-company agility and customer focus, ensuring personalized attention to every customers needs.

HVAC heating and cooling

Through a network of insulated pipes, district heating and cooling systems channel energy directly to residential and commercial buildings, ensuring a seamless supply. Gasketed plate heat exchangers are highly adjustable and you can get precisely the design and performance you’re looking for.

As awareness about the importance of adopting sustainable energy sources continues to rise, systems that leverage alternative energies are becoming ever more appealing and as experts in heat transfer technology, we design each solution to maximize performance for specific applications.

Tranter’s gasketed plate heat exchangers brings efficiency and reliability to the district heating and cooling system, capable of managing small LMTD and high NTU duties.

Geothermal energy harnesses heat from within the earth for spa resorts, heat pumps, power generation or district heating. Heat exchangers provide these systems to harness the relatively stable temperature of the earth below the surface to provide efficient power generation and heating for buildings.

Growing worldwide interest of HVAC technology is a key driver in exploring innovative methods to enhance the energy reuse efficiency. Heat pumps stand out as a sustainable solution to cut down on energy use while boosting energy reuse efficiency by increasing the temperature of low quality waste. Heat exchangers play a crucial role in heat pump systems for waste heat management systems.

Resource center

Resource center

Energy, Process industries Marine and shipbuilding Sustainability

Energy, Process industries Marine and shipbuilding Sustainability

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Still curious?